Green Manufacturing issues in machine tools

industry in terms of the life cycle

Li Congbo*, Liu Fei*, Wang Qiulian

? , Cao Huajun*

*State Key Lab of Mechanical Transmission, Chongqing University, Chongqing, China

? School of Economics & Management, Nanchang University, Nanchang, China ABSTRACT

Green Manufacturing (GM) is a kind of sustainable manufacturing mode with the full

consideration of resources consumption and environmental impact. Machine tools

industry consumes much resource and generates huge environmental emissions,

thus it is significant to gathers information about the GM issues in machine tools

industry. This study summarizes the key GM issues of the whole life cycle of machine

tools product, focusing on machine tools design, manufacturing, and use, and used

machine tools remanufacturing. And Information is acquired from the academic

literature, visits to industry, as well as through the research and practices by the

authors. Based on the key findings from the gathered information, finally, this paper

identifies the future directions of GM related areas in machine tools industry.

Keywords: Green Manufacturing (GM), machine tools industry, life cycle 1 INTRODUCTION

With the development of world economic, the global machine tools production has

increased greatly. Gardner Corp. stated the production value of the main 29 machine

tools production countries (or regions) in 2007, which is 709 billion dollars, almost

twice than that in 2003[1]. But the rapid development of machine tools industry also

brings much resource consumption and huge environment emission.

Green Manufacturing (GM), is a kind of modern manufacturing mode, which is a good

way to minimize the environmental emissions and maximize the resource utilization

during the whole product life cycle including design, manufacturing, use

and disposal,

etc [2]. The researchers are aware of the ever increasing need to address GM issues

in machine tool industry. For example, some green design and manufacturing strategies for gear cutting machines was proposed by [3]; dry cutting, semi-dry cutting

ICRM2010-Green Manufacturing,Ningbo, China

???

and little cutting fluid machining technologies were studied in [4]; machine tools

remanufacturing was researched in many literature, such as the precision parameters

of recovery parts were optimized with BP+GA hybrid algorithm in [5]. And many

companies started to engage in machine tool remanufacturing. There are already

more than 200 companies special in machine tool remanufacturing in the USA, such

as Maintenance Service Corp. and so on, and a lot of machine tool manufacturers

expanded their business to remanufacturing, too, such as DMG Group, Germany, etc.

So, it is necessary to review of GM issues associated with the machine tools industry,

which is the objective of this paper. In order to cover most of the subject in this area as

thorough as possible, the contents will be discussed in terms of the life cycle stages of

a machine tool.

2 LIFE CYCLE OF MACHINE TOOLS

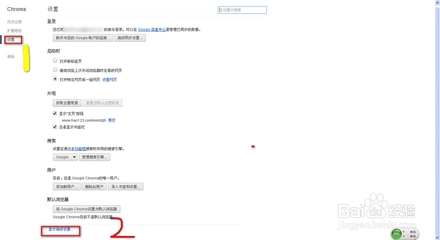

A typical life cycle of a machine tool is shown in Figure1. In the figure, four principal

stages are presented: 1) design, 2) manufacturing, 3) use, and 4) post-use.

Material

Processing

Environmental Impacts

(oil fog, dust, noise, waste

liquid, etc.)

Recovery

Use and

Maintenance

Manufacturing

Resource Consumption (raw

materials, electricity and

auxiliary materials, etc)

Disassembly

and Cleaning

Reuse

Remanufacturing

Recycling

Machine tools

Design

Figure 1. Machine tools life cycle

2.1 Design issues

Design is the leading phase during the machine tool life cycle, and the machine tool?s

performance across the whole life cycle is almost determined by design stage. Thus,

besides product structure design, material selection, process design, green design of

machine tool should consider the design for post-use stage, such design for

disassembly, design for remanufacturing, design for recycling, etc. Two green design

methods and ideas will be discussed.

1?Reduced design

For the same performance of a machine tool, resource consumption could be reduced

with smaller structure and less materials. Therefore, it is important to improve

calculating load accuracy of mechanical parts, and simplify the structure on the

Premise of Quality and function Assurance

2) Design for remanufacturing and recycling

ICRM2010-Green Manufacturing,Ningbo, China

???

The design for recycling and remanufacturing should consider how to recover the old

resources of end of life machine tools during design stage. For example, reasonable

adjustment and precision compensation measures should be set up, in order to

resume machine tools precision after Wearing; during the design of slide ways, the

repair, reuse and materials recycling measures should be taken into account.

Take the hobbing machine design for an example, its structure is shown

as figure 2.

Hobbing machine design

Bed Column

Tool

holder

Table

Back

column

Slide

unit

Electrical

system

Hydraulic

system

Figure 2. the structure of a hobbing machine

The main green design factors are considered as follows:

1) Bed

Bed is the bearing for column, slide unit, tool holder and so on. It need endure great

static force and dynamic force when machining, therefore, enough rigidity,

anti-vibration, small thermal deformation and internal stress are required when design

of machine tool bed. The GM solutions are less consumption of raw material with

hollow structural design; improvement of manufacturing process with rectangle

integral way; balancing thermal stability with symmetric design; increase remanufacturing degree with laminating, etc.

2) Column

Transmission part and precision adjusting part are contained in the large column, so

the key green design is select transmission machinery. Worm-worm gear transmission structure is recommended. Because it can obtain high transmission ratio

with single class, then amount of parts can be reduced. In another word, it can save

material.

3?Slide unit

Considering remanufacturing, HNT wearing laminating integral way can be chosen for

slide unit.

4) Tool holder

Design for disassembly is the key point in tool holder green design.

Application of

open swallow-tailed integral way is one useful approach.

2.2 Manufacturing issues

The main processes in machine tool manufacturing include foundry, forging, blanking,

jointing, mechanical machining, heat treatment, painting and assembly. ICRM2010-Green Manufacturing,Ningbo, China

???

1) Foundry Deleterious emission includes metal oxide, coke, dust, NO x , SO 2 during

the burning in cupola; polluted water emission, heat emission and noise are the other

environmental impacts.

2) Forging Heat emission and noise are the main GM issue. Besides, solid waste as

lubricant oil, slag and ferric oxide are produced, too.

3) Blanking Noise impact is serious in blanking process, and the other problems are

scrap and oil leak.

4) Mechanical machining During mechanical machining, waste oil emission from

lubricating system, cooling system and transmission system, etc. is the key fluid

emission. Solid emission includes metal chip, power, scrap, inferior and so on.

5) Jointing Soot emission is inevitable when jointing, and fire danger is

accompanying. In addition, there is blasting danger because of gas leak. Welding wire

and chip are the solid wastes.

6) Heat treatment Heat treatment will produce air emission, fluid emission and heat

emission. In which, air emission includes oil gas, vapour, CO, NH 3 , NO X , nitrate

vapour, etc. Physical pollution such as electromagnetism pollution exists, too.

7) Painting Chemical emission is the main environmental impact, including painting

fog, benzene, dimethylbenzene, acid mist and alkali mist, etc. the disposal of waste

lacquer, lacquer container, wipes and protective equipment, etc. are important.

8) Assembly Noise from mechanical and pneumatic equipments, leak of oil and

inferior are the main GM issue.

2.3 Use issues

The use stage of a machine tool is actually the process to machining parts, which also

has both the resource consumption (mainly electrical energy, cutting fluid, cutter) and

the creation of wastes (fluid emission, air emission, etc.)

In fact, most electric power is wasted during machine tool use phase. According to

statistic data, during the machine tool use course, only 25% power is acted on

machining, and the rest is wasted[6]. In order to save electrical energy, the no-loading

power should be minimal, and reducing the weight of machine tool is one useful way.

Cutting fluid is very harmful to the environment and the workers, so it is necessary to

reduce the utilization of cutting fluid and its emission during the use stage of machine

tool. The best alternative way is to adopt dry cutting, which does not need cutting fluid

at all. And Minimized Quantity Lubrication (MQL) is also an effective way to solve this

problem, but it needs specific equipment to provide cryogenic cold air. Another important GM issue in the use stage is green process planning (GPP), which

also could save energy and reduce the environmental impact in the machining

ICRM2010-Green Manufacturing,Ningbo, China

???

process. The key GPP issues include selecting of process parameters, machine tools,

fixtures and coolants, and optimizing the process routines, etc.

2.4 Post-use issues

Collection of

Uesed Machine

Tools

Disassembly

Cleaning

Inspection

and Sorting

Redesign of

Machine Tools

Machine-based

Remanufacturing

? Functional

? CNC rebuilding

? Energy-saving Upgrading

? Informational Upgrading

? ? ?

Inventory of

Remanufactured

Parts

Parts-based Remanufacturing

Iron Castings (such as

the Bed)

Other Disposed Parts

Wearing Parts

Precision Parts(such

as the Spindle)

Disposal

Recycling or reuse

as spare parts

Reuse after

Remanufacturing

Direct Reuse

Reassembly

and Testing

Remanufactured

Machine Tools

Markets and

Customers

New Parts

Purchasing

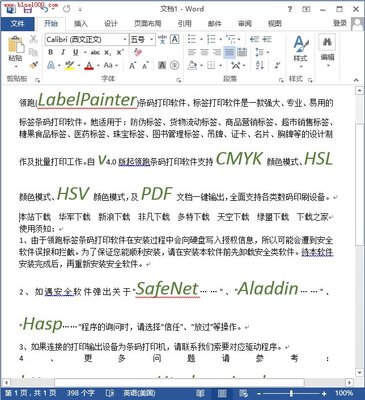

Figure 4?The recovery process of used machine tools

Machine tool is one of the typical equipments to be remanufactured and recycled with

high value. The structure castings after Natural Aging can be reused with high rate,

which are 60~70 percent in weight of the whole product. In addition, there are a large

amount of used and old machine tools to be recovered because of functional and

technologic limitations. For example, according to statistics, there are about 5500

thousand machine tool in China at present, and 60% have serviced over ten years.

The recovery process of machine tools could be shown as figure 4, including

disassembly, cleaning, inspection, sorting, redesign, remanufacturing and

reassembly. Generally, remanufacturing include part-based remanufacturing and

machine-based remanufacturing, and the latter is the main recovery way, because the

old machine tool can be easily remanufactured and updated to a high quality level

with low cost with the development of the machining technology, the automation and

CNC technology, etc.

3 SUMMARY

As one of the foundational equipment manufacturing industries, machine tools

industry brings much resource consumption and huge environment emission, through

the whole life cycle. Green manufacturing issues surrounding each stage of the life

cycle are presented, including design issues, manufacturing issues, use issues and

post-use issues. The future directions of GM issues in machine tools industry may

focus on the following topics:

ICRM2010-Green Manufacturing,Ningbo, China

???

(1) Design: development of technologies and methods to support the design of

ecological machine tool, such as much lighter machine tools, dry machine tools;

design of machine tools with new structure, such as parallel machine tool.

(2) Manufacturing: reducing waste and improving energy and materials efficiency of

processes, including foundry, forging, jointing, heat treatment, painting, etc.

(3) Use: monitoring of machining process for the study of energy consumption, and

integrating energy recovery systems into machine tools; development new equipments to reduce emissions in the machining;

(4) Post-use: establishing and optimizing the reverse logistics of used machine tools,

development specific equipments for disassembly and cleaning, development of new

technologies for part recovery.

ACKNOWLEDGEMENTS

This work was supported by National Science Foundation of China (50605066) and

National Key Technology R&D Program of China (2006BAF02A01).

REFERENCES

[1] Xu, S.Z. (2008) Analysis on world machine tool production and sales in 2007.

Manufacturing Technology & Machine Tool. Vol. 4, pp.10-11.

[2] Liu, F., Cao, H. J., Zhang, H. (2005) The Theory and Technology of Green

Manufacturing. Science Press number ISBN 7030144198.

[3] Li, X. G., Liao, S. H., Cao, H. J., Liu, F.(2003) Green Design Strategies of Gear

Machine Tool and Application. Manufacturing Technology & Machine Tool. Vol.

11, pp.18-20.

[4] Weinert, K., Inasaki, I., Sutherland, J. W., et al.(2004) Dry machining and

minimum quantity lubrication. CIRP Annals - Manufacturing Technology. Vol. 53,

pp. 511?537.

[5] Ding, W. Z., Huang, X. D., Zhou, M. H. (2007) Study On Precision Distribution

among Restorable Parts and Componets of Remanufactured Machine tool. Mechanical Science and Technology. Vol. 26, pp. 1466-1470.

[6] Zhang, S. (2008) Next Generation Production System. World Manufacturing

Engineering & Market. Vol. 2, pp. 52-55.

ICRM2010-Green Manufacturing,Ningbo, China

???

ICRM2010绿色制造,宁波,中国

机械工具中的绿色制造问题

产业的生命周期

绿色制造(GM)是一种可持续的生产模式,在充分考虑资源消耗和环境影响。机床产业消耗大量资源,产生巨大的环境排放量,因此重要的是收集关于转基因问题的信息在机床产业。本研究总结了机床产品全生命周期的关键通用问题,重点对机床的设计,制造,使用,和使用的机床再制造。信息是从学者文学中获得,访问行业,以及通过研究和实践,作者。基于所收集的信息的主要结果,最后,明确转基因相关领域的机床行业的未来发展方向。

关键词:绿色制造(总经理),机床工业,生命周期

1引言

随着世界经济的发展,全球机床生产大量增加。加德纳公司表示,29的主要机床生产国家(或地区)生产总值的2007,这是7090亿美元,近2倍比2003 [ 1 ]。但快速发展的机床行业带来了大量的资源消耗和环境排放的巨大

绿色制造(GM),是一种现代制造模式,它是一种很好的方法来减少对环境的排放,最大限度地提高资源利用率在整个产品生命周期包括设计、制造、使用和处置等[ 2 ]。研究人员意识到越来越需要解决通用问题的机床工具行业。例如,提出了齿轮切割机的一些绿色设计和制造策略,提出了3种方法:干切削、半干切削和小的切削液加工技术[ 4 ]研究了工具再制造;机在许多文献的研究,如精度参数恢复部分与BP + GA混合算法优化[ 5 ]。和许多公司开始从事机床再制造。已经有超过200家公司在美国再制造专用机床,如维修服务有限公司等,以及大量的机床制造商扩大他们的业务,再制造,如DMG集团、德国等。

因此,有必要对与机床行业相关的通用问题进行回顾,这是本文的目的。为了覆盖大部分的主题在这个地区彻底越好,内容将在各生命周期阶段的机床方面讨论。

2机床寿命周期

一个典型的机床生命周期如图1所示。在图中,四个主要阶段:1)设计,2)制造,3)使用,和4)后使用

2.1设计问题

设计是机床生命周期中的领先阶段,机床?在整个生命周期的性能是由设计阶段基本确定。因此,除了产品结构设计、材料选择、工艺设计、绿色设计机床应考虑后期使用阶段的设计,可拆卸设计,面向再制造的设计、面向回收的设计,等两绿色设计方法和思路进行讨论。

1)减少设计的机床性能相同,可以减少资源消耗较小的结构和材料。因此,它是提高计算准确性的重要零部件的机械负荷,简化了结构和功能的前提下,质量保证

2)再制造和回收的设计

回收再制造的设计应考虑如何在设计阶段中恢复生命机械工具的旧资源。例如,合理的调整和精度补偿措施应建立,以恢复机床精度后穿;滑道,装修设计时,再利用和材料回收的措施应考虑。

以滚齿机的设计为例,其结构如图2所示。

主要的绿色设计因素被认为是如下:

1)床

床是立柱、滑块、刀架等的支承轴承。它需要承受很大的静力和动力时的加工,

因此,足够的刚度、抗振性、热变形小、内应力时所需设计的机床床身。通用的解决方案是采用空心结构设计的原材料消耗较少;采用矩形整体方式改善生产工艺;平衡热稳定性与对称设计;增加再制造度;

2)柱子

传动部分和精度调整部分包含在大柱,所以关键是选择传动机械的绿色设计。蜗轮蜗杆齿轮传动结构的建议。因为它可以获得更高的传输率与单独的类,然后可以减少零部件数量。用另一个词,它可以节省材料。

3?滑动装置

考虑再制造,HNT穿层压积分的方式可以选择滑动单元。

4)工具支架

面向拆卸的设计是工具夹持器绿色设计的关键。应用开放式燕尾积分方法是一种有用的方法。

2.2制造问题

机床制造中的主要工序包括:铸造、锻造、冲裁、焊接、机械加工、热处理、喷漆和装配。

1)铸造有害排放包括金属氧化物、焦炭、灰尘、NO x,所以2冲天炉在燃烧;水污染排放、热排放和噪声等对环境的影响。

2)锻造热辐射和噪声是主要的通用问题。此外,固体废物作为润滑油,炉渣和氧化铁的生产,也。

3)冲裁噪声对消落过程中的影响是严重的,其他问题都是废料和油泄漏。

4)在机械加工机械加工,从润滑系统废油排放、冷却系统、传动系统等关键任务,是流体。固体排放包括金属芯片、电源、废料、劣质等。

5)焊接烟尘排放是不可避免的,当焊接时,火灾危险伴随着。此外,还有爆破危险,因为气体泄漏。焊接线和芯片是固体废物。

6)热处理热处理会产生空气排放,流体排放和热排放。其中,空气排放包括油气、蒸气、CO、NH 3、NO x、硝酸蒸气等物理污染如电磁污染的存在,太。

7)油漆化工排放是主要的环境影响,包括苯、二甲苯、漆雾、酸雾和碱雾等处理废漆、漆容器、抹布和防护设备等都是重要的。

8)机械、气动设备装配噪声,油气泄漏是主要的通用问题。

2.3使用问题

机床的使用阶段实际上是加工零件的加工过程,同时也具有资源消耗(主要是电能、切削液、刀具)和废物的产生(液体排放、空气排放等)。

事实上,大多数电力是浪费在机床使用阶段。根据统计数据,在机床使用过程中,只有25%的功率在机械加工中起作用,其余的则是浪费6。为了节省电能,无负载的功率应该是最小的,并减少机床的重量是一个有用的方式。切削液对环境和工人都是有害的,因此在机床使用阶段减少切削液的使用和排放是十分必要的。最佳的选择方式是采用干切削,不需要切削液。和最小量润滑(MQL)是解决这一问题的有效途径,但它需要特定的设备提供低温冷空气。

在使用阶段的另一个重要的通用的问题是绿色工艺规划(GPP),并能节省能源和减少在加工过程中对环境的影响。GPP的关键问题包括工艺参数、机床的选择、夹具和冷却液,并优化工艺路线,等等。

2.4后使用问题

机床是制造和高价值回收的典型设备之一。自然老化后的结构件可以重复使用,在整个生产过程中,其质量是60,百分之70。此外,还有大量的使用和旧机床

的功能和技术的限制,以恢复。例如,据统计,目前中国有大约550万台机床,60%年来已经提供了超过十年的服务。

机床回收过程可如图4所示,包括拆卸、清洗、检查、整理、再设计、再制造和组装。一般来说,再制造包括部分基于再制造和机器的制造,后者是主要的回收方式,因为旧机床再制造和更新可以很容易地以低成本和高质量的加工技术的发展水平,技术,自动化和数控等。

3总结

作为基础装备制造产业之一的机床制造业,通过整个生命周期,带来了大量的资源消耗和巨大的环境辐射。绿色制造问题,围绕生命周期的每个阶段,包括设计问题,制造问题,使用问题和后使用问题。在机床行业未来的发展方向,可能会集中在以下主题:

(1)设计:开发的技术和方法,以支持生态机床的设计,如轻得多的机床,机床;机床;设计新的结构,如并联机床。

(2)生产:减少浪费,提高能源和材料效率,包括铸造、锻造、焊接、热处理、喷漆等。

(3)使用:监测能源消耗的研究加工过程,并将能量回收系统整合到机床;开发新设备,以减少机械加工中的排放量;

(4)使用后:建立和优化所使用的机床的逆向物流,开发具体的拆卸和清洗设备,开发新技术用于零件回收。

致谢

这项工作得到了国家自然科学基金(50605066)和中国科学基金会的资助 国家关键技术研发项目(2006baf02a01)。

引用

[ 1 ]徐,深圳(2008)在2007世界机床生产和销售分析。

制造技术与机床。4卷,pp.10-11。

[ 2 ]刘、楼、曹、张、H(2005)绿色理论与技术

制造业。科学出版社ISBN号7030144198。

[ 3 ]李,X,辽,美,曹,曹,刘,楼(2003)绿色设计策略

机床及应用。制造技术与机床。卷。

11、pp.18-20。

[ 4 ] Weinert,K.,稻崎,即萨瑟兰,J. W.等人(2004)干法加工 最小量润滑。CIRP通志-制造技术。卷53,

511页?537。

[ 5 ]丁W Z.,黄X博士,周,M. H.(2007)精度分布研究

可修复零部件再制造机床部件之间的。

机械科学与技术。卷26,页1466-1470。

[ 6 ]章,第(2008)下一代生产系统。世界制造业

工程及市场。卷2,页52-55。

百度搜索“爱华网”,专业资料,生活学习,尽在爱华网

爱华网

爱华网