罗氏研发支持楼项目

Roche R&D Building Project

施工方案

Construction Scheme

(消防系统部分)

(Fire-Proof System Part)

编制人Maker:

审核人Checker:

批准人Approver:

版本C Editon C

江苏省建设集团公司(沪)Jiangsu Construction Group Com

目 录 Contents

第一章:编制说明及依据 ............................................................................................................... 2

1.1编制说明:preparation instructions ................................................................................. 2

1.2 编制依据: Develop basis ............................................................................................. 3

1.3工程施工目标:Construction goals: .................................................................................. 4

第二章 工程简介及概况Chapter II Introduction and Overview of the project ........................ 5

2.1工程简介Project Overview ................................................................................................ 5

2.2工程概况Project Overview ................................................................................................ 6

2.3系统设计概况 System design Overview ............................................................................ 6

第三章 施工部署Chapter 3 Construction deployment ........................................................... 7

3.1人力资源分析及工具配备 human resources analysis and equipped tools .................. 7

3.2 主要人员职责 Major staff responsibilities .............................................................. 10

3.3安装人员部署installation personnel deployment ....................................................... 14

3.4 施工顺序安排 Construction sequencing ..................................................................... 15

3.5施工管理措施 construction management measures ................................................... 15

3.6施工技术准备 Construction technology preparation .................................................. 17

3.7施工器具设备Construction machinery equipment ..................................................... 19

3.8工程施工协调 construction coordination .................................................................... 20

3.9材料设备进场计划:Materials and equipment site entering plan: ............................. 22

第四章 施工方案construction program ..................................................................................... 23

4.1 火灾自动报警及联动控制系统Automatic fire alarm and linkage control system ...... 24

(1).施工工艺流程Construction process .................................................................. 24

(2).主要分项工程施工方法及技术要求 ................................................................. 24

Major sub engineering construction methods and technical requirements ................... 24

三、施工难点及相应措施 construction difficulties and corresponding measures ..... 35

4.2 自动喷水灭火喷淋系统 Automatic sprinkling fire extinguishing system .................. 38

一、施工工艺流程:construction flow......................................................................... 38

二、系统施工准备 system construction preparation .................................................. 38

三.主要分项工程施工方法及技术要求 ..................................................................... 41

Major sub engineering construction methods and technical requirements ................... 41

4.3 消火栓系统及消防设备安装Fire hydrant system and fire equipment installation .... 55

一.施工工艺流程 Construction process ..................................................................... 55

二、主要分项工程施工方法及技术要求 ..................................................................... 56

Major sub-project Construction methods and technical requirements .......................... 56

4.4 沟槽式连接管道专项方案 ............................................................................................ 60

一.施工工艺流程 Construction process ..................................................................... 60

二、主要分项工程施工方法及技术要求 ..................................................................... 60

Major sub-project Construction methods and technical requirements .......................... 60

第五章、工程质量保证措施engineering, quality assurance measures ...................................... 64

第六章、安全技术措施safety technical measures ...................................................................... 66

6.1、施工安全 construction safety?????????????????????67

6.2、材料、机械安全materials, machinery and safety???????????67

6.3安全防火措施。Fire safety measures?????????????????68

6.4登高作业ascending job???????????????????????错误!未定义书签。

6.5施工垃圾处理措施Construction waste disposal measures?????????68

6.6成品保护:Finished product protection ????????????????68

6.7文明施工The construction of civilization?????????????69

6.8危险分析???????????????????????70

第一章:编制说明及依据

1.1编制说明:preparation instructions

本施工组织设计主要反映本专业的基本施工方法,,采用经济、合理、安全可靠

的施工方案编制而成的。The construction organization design reflects the professional construction methods, the use of economic, reasonable, safe and reliable construction program is compiled.

我们在认真分析了本工程的特点、难点、重点及各种影响施工的因素,充分融入了

我们多年来对类似工程的经验和对业主招标文件、图纸的充分理解,对给排水专业安装部分的管理机构设置、施工进度计划、劳动力组织、机械设备配备、物料的采购供应、主要分项工程的施工方法、进度控制措施、工程质量控制措施、安全保证措施、文明施工及环境保护措施等诸多因素进行了综合考虑和研究,以突出本施工组织设计在罗氏制药研发支持楼项目电气专业施工过程中对本专业目标系统控制的科学性、可行性和指导性。In a careful analysis of the characteristics of this project, the difficulties, the focus and the various factors affecting the construction, fully integrated into our many years of experience in similar projects and full understanding of the owners of tender documents, drawings, professional installation part of the water supply and drainage management structure, the construction schedule, labor organizations, machinery and equipment with procurement and supply of materials, construction methods of the major sub-project, the progress of control measures, engineering, quality control

measures, safety assurance measures, civilized construction and environmental protection measures, and many the factors considering and research, Roche R & D support building project the electrical professional construction process of the scientific nature of the professional control of the target system, the feasibility and guidance designed to highlight this construction organization.

1.2 编制依据: Develop basis

罗氏制药研发支持楼项目工程的招标文件;Roche pharmaceutical R & D support building project tender documents;

罗氏制药研发支持楼项目机电工程的设计图纸; Roche pharmaceutical R & D support floor mechanical and electrical engineering design drawings;

《建筑设计防火规范》GB50016-2006

Architectural design code for fire protection GB50016-2006

《高层民用建筑设计防火规范》GB50045-95(2005年版)

Tall Buildings "design code for fire protection GB50045-95 (2005)

《自动喷水灭火系统设计规范》GB50084-2001(2005年版)

"Automatic sprinkler system design specifications" GB50084-2001 (2005 edition) 《火灾自动报警系统设计规范》GB50116-98

Automatic fire alarm system design specifications "GB50116-98

《火灾自动报警系统施工及验收规范》GB50166-2007

Automatic fire alarm system construction and acceptance "GB50166-2007

《自动喷水灭火系统施工及验收规范》GB50261-2005

Automatic sprinkler system construction and acceptance GB50261-2005

《建筑给水排水及采暖工程施工质量验收规范》GB50242-2002

Building Water and Heating Engineering Quality Acceptance specifications "GB50242-2002

《建筑电气工程施工质量验收规范》GB50303-2002

"Construction Quality Acceptance and electrical engineering specifications" GB50303-2002

《点型感烟火灾探测器》GB4715-2005

"Point-type smoke detector GB4715-2005

《点型感温火灾探测器》GB4716-2005

Point type heat fire detectors, GB4716-2005

《火灾报警控制器》GB4717-2005

Fire alarm control GB4717-2005

《手动火灾报警按钮》GB19880-2005

"Manual fire alarm button GB19880-2005

《消防联动控制系统》GB16806-2006

"Fire control system" GB16806-2006

《消防控制室通用技术要求》GA767-2008

General technical requirements for the fire control room "GA767-2008

相应的国家规范、标准;relative national norms and standard

本专业历史上类似工程的经验 ;similar to the major project experience

本专业质量体系和健康环境体系文件;quality system and health environment document

1.3工程施工目标:Construction goals:

1.3.1质量目标Quality Goals

本专业安装工程的质量控制目标:交给业主一个既满足国家规范要求又让业主满意的合格产品。The professional installation engineering quality control objectives: to the owners

both satisfied with letting owners of qualified products meet national regulatory requirements.

1.3.2工期目标

消防专业标段工程我们依假定开工日期为2013年6月1日,2013年12月15日结束,共计199个日历天;验收时间:2013.12.1—2013.12.15。

Fire project, we due to start on June 1st ,and finish on December 15th ,2013, 199 calendar days in all . Acceptance time: 2013.12.1—2013.12.15。

1.3.3安全目标 Security Goals

施工工程中,本专业将采取切实可行的措施和充足的安全投入,建立完善的安全施工管理机制,确保本项目施工全过程无重大伤亡事故、无火灾事故和无恶性中毒事件目标。Construction project, the professional will take practical measures and adequate investment in safety, establish and improve the safety of construction management mechanisms to ensure that the whole construction process of this project without major casualties, no fire accidents,, and malignant poisoning target.

The duration targets

1.3.4环境保护和文明施工目标 Environmental Protection and civilized construction target

本专业将严格按照上海市有关建筑工程施工的各项管理规定执行,加强施工组织和现场安全、文明施工管理。成为既满足设计要求又满足建筑物使用功能的绿色建筑,我们将严格按照环保体系的重点来实施本专业项目。This professional will perform in strict accordance with the regulations on building construction in Shanghai, strengthen the construction organization and on-site security, civilized construction management. Both meet the design requirements and meet building use green building, we will be in strict accordance with the focus of environmental protection system to the implementation of the professional project.

1.3.5团结合作目标 unity and cooperation goals

积极、主动、高效为业主服务,急业主所急,想业主所想,处理好与业主和综合管理团队、监理、设计、各标段分包及相关政府部门的关系,使工程各方面形成一个团结、高效、和谐、健康的有机整体,努力促进项目综合目标的实现。Positive, proactive, efficient service for the owners, anxious owners are anxious owners that want to deal with the owners and management team, supervision, design, each section of sub-contractors and relevant government departments, so that all aspects of the project to form a organic whole unity, harmony, health, efforts to promote the goals of the project.

第二章 工程简介及概况Chapter II

Introduction and Overview of the project

2.1工程简介Project Overview

工程名称:罗氏制药有限公司研发支持楼 Project Name: Roche Pharmaceutical Co., Ltd. R &

D support floor

建设单位:上海罗氏制药有限公司 Construction Unit: Shanghai Roche Pharmaceutical Co., Ltd.

设计单位:信息产业电子第十一设计研究院科技工程股份有限公司 Design Unit: The Eleventh Design and Research Institute of Information Industry Technology Engineering Co., Ltd.

人防设计单位:上海民防建筑设计研究院有限公司Civil air defense design units: Shanghai Civil Defence Institute of Architectural Design Co., Ltd.

监理单位:上海同济工程项目管理咨询有限公司Supervision Unit: Shanghai Tongji Construction Project Management Consulting Co., Ltd.

建设地点:上海市浦东新区龙东大道1100号 Construction Location: Long Dong Avenue, Pudong New Area, Shanghai, 1100

2.2工程概况Project Overview

本工程位于上海市上海张江高科技园区,大楼北侧为龙东大道,南侧为李时珍路,

东侧为日月光厂区,西侧为勃林格殷格翰厂区;本大楼为罗氏老厂区内新扩建的一幢技术研发支持楼,大楼编号为11#,占地大约在1800多平米,建筑面积为10600 平方米,分为地上五层、地下一层。厂区北侧的入口为进入现场的主要入口。现场已有的靠近罗氏二期项目的建筑为位于东南的餐厅(B-01),南侧的办公楼(B-02),西侧的生产大楼(B-03)。This project is located at Shanghai Zhangjiang Hi-tech Park, to the north of the building is Longdong Avenue, to the south Lishizhen Road, to the east Riyueguang Plant, to the west Boehringer-Ingelheim Plant; this building is a R&D building inside the former plant that is to be rebuilt, the building number is 11#, with an total area of 2000 kilo meters and 5 floors above and one underground. The north gate is the main entrance of the site. The buildings next to the Roche II Project include one canteen (B-01) at the southeast, and one office building at the south, and the production building (B-03).

2.3系统设计概况 System design Overview

本大楼分为地下一层,地上五层。此大楼的消防工程包含:消防喷淋系统、消火

栓系统、火灾报警系统以及广播系统。喷淋及消火栓系统水源直接由原室外环状消防管网引出两 路DN150管道接入本大楼,不需另设水泵房。消防报警系统为独立系统,单独增设消防报警主机于8#门卫室。广播系统主机设置在11#楼报警室,通过网络与8#门卫室原有系统连接。The building contains one floor underground, and five floors

above. Building fire protection engineering system includes: fire sprinkler system, fire

hydrant system, fire alarm system, and the broadcasting system. Sprinkler and hydrant

system water leads to two DN150 pipeline brought directly from the outdoor cyclic fire

control network access to the building, without a separate pump house. The fire alarm

system as an independent system, separate additional fire alarm host # guard room.

Broadcasting system host set in the 11 # building alarm room, the original system

connected through the network with 8 # guard room.

第三章 施工部署Chapter 3

Construction deployment

3.1人力资源分析及工具配备 human resources analysis and equipped tools

人员合理配备是项目进度计划和项目质量的一大保证。通过多年在项目实施过中所得出的经验,我们通常把项目进行阶段划分,从而达到科学化管理。对于这个项目,我们把它划分为项目准备阶段、管道预埋阶段、套管预埋阶段管道安装阶段、设备安装阶段、系统调试阶段、竣工验收阶段、后期文档移交阶段、质量保证阶段。通过划分我们就更加清晰明了地知道在每个阶段所需的人员数量、工种、容易出现问题环节等等,如我们在配管安装阶段,在这阶段我们所需要的技术工种人数要占总施工人数的80%以上,20%以下的施工人员用来对一些前期未能完成的工作进行完成和对安装人员的协助工作。本专业负责人将以工程项目管理为核心,以优质、高速、安全、环保、文明为主轴,加强动态、科学管理,优化生产要素,精心施工,大力推广先进施工技术,在确保质量的同时,力争提前完成施工任务,从文件控制、材料采购到产品标识、过程控制等过程中,切实执行ISO9001 标准和质量保证体系文件,达到创优质高效的目标。Reasonable human resources distribution is a major guarantee of project schedule and project quality. According to our past experiences accumulated through many years of practices, we usually divide the project into different parts so as to achieve

scientific management. As for this project, we plan to divide it into project preparation phase, pipeline embedding phase, casing pipe pre-buried phase, pipeline installation phase, equipment

installation phase, system debugging phase, completion and acceptance phase, later document handover phase and quality assurance phase. Through this, we can get familiar with the relevant information in each phase, including the number of personnel, work type and specific parts where some problems may happen; for example, at pipeline installation phase, technical personnel should take up 80% of all construction worker, the rest 20% will help to finish some work that is not finished at preliminary. This project manager shall focus on engineering management, based on high quality, high speed, safety, environment protection and civilized engineering. We will try our best to finish the construction ahead of time, at the premise of guaranteeing the quality. We will follow the ISO9001 standard and quality assurance document to achieve our goals.

劳动力进场计划表:Labor force enter site schedule

劳动力动态计划表:Labor force dynamic schedule

版本:C

第 8 页 共 72 页

消防系统进度计划表:详见附件(一)

The progress of the fire protection system schedule: see Annex (1)

本项目按照《建设工程项目管理规范GB/T50326》组成的项目经理负责制,对工程进度、质量、安全、文明施工、合同履约全面负责,确保工程按照既定质量,进度目标交付使用,同时所有各职能部门都配合项目经理的实施。This project follows construction engineering project management regulations GB/T50326 and the project manager is in total responsible for the construction schedule, quality, safety, civilized construction and contract compliance, so as to ensure that it will meet quality and construction date requirements, and that all departments cooperate with the project manager.

版本:C

第 9 页 共 72 页

3.2 主要人员职责 Major staff responsibilities

3.2.1项目经理Project Manager

1)具体负责项目施工生产的技术、质量、安全、进度的组织、控制和管理工作以及协助项

目经理分管工程部、安全部、质量部、办公室等部门的工作;Assist on project manager’s work, specifically responsible on project construction’s technical, quality, safety and schedule’s organization, control and management. Assist project manager to manage engineering division, safety division, quality control division and office work.

2)具体负责项目质量保证计划、各类施工技术方案和安全文明施工组织管理方案的编制和落实工作;Specifically is responsible for the project quality to guarantee the plan, each kind of construction technical plan and the safety civilization construction organization management plan’s establishment and the carry out of work;

3)负责总体和阶段进度计划的编制、分解、协调和落实工作;Responsible for the overall and the stage progress plan establishment, the decomposition, the coordination and the carry out of work;

4)负责项目质量目标、进度目标、安全文明、环保施工目标和质量奖目标的策划、组织、

版本:C

第 10 页 共 72 页

管理和落实工作;Responsible for the project quality goal, the progress goal, the safety civilization, the environmental protection construction goal and the quality prize goal plans, the organization, the management and the carry out of work; 5)负责与建设单位、监理单位等现场协调和沟通的组织领导工作;Responsible with the construction unit, the overseeing unit and so on the site coordination and the communication organization leadership work;

6)参与供应商选择的组织工作;Participates in organization work which the supplier chooses;

7)协助技术负责人进行新材料、新技术、新工艺在本工程的推广应用和技术总结工作;The assistance technical person in charge carries on the new material, the new technology, and the new craft in this project promoted application and the technical summary work;

8)具体负责工程的技术资料整理、阶段交验和竣工交验工作的组织领导工作。Specifically is responsible for the project the technical data to reorganize, organize and lead the stage furnishes for examination and completion furnishes examination work. 3.2.2专业工程师 Professional Engineer

1)熟悉本专业的质量验收规范,保证施工过程符合图样、规范及合同要求,使过程质量达到预期标准。Be familiar with the professional quality acceptance standards, so as to ensure that the construction process is in line with the drawings, specifications and contract requirements and reach the expected standard quality.

2)按施工组织设计和施工方案的要求精心组织施工,使本专业项目在施工过程中处于受控状态。参加生产例会,认真填写施工日志和质量记录。Organize construction in strict accordance with the design and plan. Keep the discipline in the construction process in a controlled state. Participate in the production meeting, and fill out construction log and quality records.

3)熟悉本工程有关专业图样,对分部、分项工程的作业班组进行书面的技术和安全交底,保证施工按规定程序、规程进行。Be familiar with the works of professional drawings, written technical and safety tests, operating segment, the sub-project team to ensure that the construction according to prescribed procedures, procedures. 4)负责对过程参数、产品特性进行监控,发现偏差按有关规定及时采取措施,参与对特殊

版本:C

第 11 页 共 72 页

过程作业人员持证上岗的鉴定工作。Be responsible for the monitoring of process parameters and product characteristics, and if there is any deviation, according to relevant provisions, take timely measures to identify the personnel’s involved in the operating process and check whether they have special certificates.

5)负责本工种或专业的用工、用料计划工作。Be responsible for labor distribution and material planning work of certain work type or discipline.

6)负责组织自检、交接检及分项工程质量的评定工作。Be responsible for organizing the self-test, handover inspection and assessment of each division work.

7) 负责贯彻执行文明施工管理的各项规定,做到安全生产。Be responsible for implementing the provisions of the civilized construction management, and ensure safety production.

3.2.3安全员 Safety Officer

1)配合项目经理编制工程的安全施工方案,并督促方案的贯彻实施。Cooperate with the project manager or foreman for the engineering construction safety plan and urge the

implementation of the program.

2)负责对进入现场的施工人员进行入场安全教育。Be responsible for the construction workers to enter the scene and accept safety education.

3)负责对施工人员的安全操作进行监督、检查和技术指导。对违章指挥、违章作业、冒险蛮干现象进行制止、纠正和处罚。Be responsible for the supervision, inspection and technical guidance on the safe operation. Any Illegal command, illegal operations, savage phenomena must be corrected and punished.

4)配合项目负责人对现场的安全防护措施进行检查和验收。Cooperate with the person who is responsible for the check and acceptance of the on-site security measures.

5)对不安全的隐患,监督有关人员进行整改。Find out potential hazards and urge relevant person to rectify them.

6)负责对安全技术交底进行审核、签字。Be responsible for the audit of security technology correspondent signature.

7)协助施工负责人对现场的各类安全事故进行调查、分析、记录、报告、处理及制定防范措施。Assist the construction person in charge of all types of safety to the scene of the accident investigation, analysis, recording, reporting, processing and the development of preventive measures

3.2.4材料员Material member

1)负责材料供方的评价(必要时会同有关部门)、供方档案资料搜集及合格供方的报批工作;Responsible for material supply-side evaluation with relevant departments (if necessary), the supply-side file data collection and qualified for the approval of work;

2)负责根据生产部门编制的材料月度需用计划,汇总编制物资采购计划并报请领导审批,到合格供方进行采购。Responsible for the monthly materials required plan .Prepare in accordance with the production department, summary of the preparation of the material procurement plan and report to the leadership for approval, qualified for the procurement.

3)负责进场材料的验收、标识、记录,严格履行物资复试、发放的流转程序,正确掌握各种材料的复试批量,做好与技术、试验部门的接口工作。与相关部门配合做好材料追溯工作。发现不合格材料时,进行标识并及时通知有关部门进行评审和处置,填写《不合格物资处置记录表》,并报料具处备案。Be responsible for the acceptance of the approach the material, logos, records, strictly fulfill the material re-examination, payment of the transfer process,

correctly grasp the batch of re-examination of a variety of materials, good interface technology, and test departments. Good material retrospective work in conjunction with the relevant

departments. Found substandard materials, identify and promptly notify the relevant authorities for review and disposal fill the substandard material disposal record sheet, and rebellion with at filing.4)负责按规定要求进行现场和仓库材料的搬运、贮存、标识以及维护,达到文明施工场容管理 要 求。Be responsible for the site and the warehouse material handling

requirements, storage, labeling, and maintenance to achieve the the civilized Construction field content management requirements.

5)负责主要材料发放定额管理,一般材料做到出有凭入有据,手续齐全,为材料成本核算提供可靠依据。Be responsible for the main material issuing quota management, general materials do with the grounds, complete the procedures to provide reliable basis for material costing.

6)负责现场材料在使用过程中,按各项规章制度严格规范管理,协助项目部监督班组材料的合理使用,搞好材料的回收利用及修旧利废工作,减少材料的积压和浪费。site material during use, according to the rules and regulations strictly regulate the management, to assist in the project department supervision team rational use of materials, do a good job in the recycling of materials, and repair old work to reduce the backlog of material and waste.

7)负责对顾客提供物资的验证、标识、记录、贮存、维护等管理工作。发现物资有问题,及时标识并通知“建设单位”,填写《顾客提供产品发生问题通知单》,并报料具处备案。Be responsible for the customer to provide material verification, identification, recording, storage, maintenance and management. Materials, timely identification and notification of the

construction unit, fill in the customer products of trouble tickets, and rebellion, with the Department for the record.

8)认真填写各项台帐、报表、记录,按时向有关部门上报。Fill in the various accounting statements, records, and timely reported to the authorities.

3.2.5资料员 Data Members

1)负责本专业文件和技术资料的收发、管理资料,确保使用有效文件和资料。负责保管工程施工图样及变更洽商汇录,工程竣工后在规定的时间内将竣工图修改整理完毕、装订成册,按规定移交有关单位和部门。The transceiver is responsible for the professional and technical information and management information to ensure the use of valid documents and information. Responsible for the custody of construction drawings and changes negotiated exchange recorded, and plans to modify finishing after the completion of the project will be completed within the stipulated time is completed, bound, and provides for the transfer of the relevant units and departments.

2)收集整理工程的全部资料,按照市建委、城建档案馆的规定标准装订成册,竣工后按期移有关单位和部门。Collect the preparation works all the information, in accordance with the provisions of the standard of the Municipal Construction Committee, Urban Construction

Archives bound volumes, after the completion of scheduled transfer of units and departments.

3)负责项目部测量、计量器具的检测、标识管理工作。Responsible for project Ministry of measurement, measuring instruments detect identity management.

4)参与编制施工方案,办理工程洽商。Participate in the preparation of the construction program to handle engineering negotiated.

3.3安装人员部署installation personnel deployment

1) 根据土建对施工区域的划分和总体进度的计划安排,本专业组织10-15人、根据进度动态组织人员进场,安排生活,登记并进行进场教育。Arrange according to the plans of the civil

division and the overall progress of the construction area. This discipline organizes 6-10 workers, which will enter the site dynamically. The workers must receive site education and registration.

2)根据本工程施工场地窄小的实际情况和上述劳动力的组织,我们把本专业安装分成2-3个专业安装小组,分别在不同的楼面或者不同的作业区展开专业流水作业,according to the actual situation of the construction site narrow and the labor organizations, the professional

installation professional installation team into 2-3, respectively, in different floor or different work area to expand the professional flow shop

3.4 施工顺序安排 Construction sequencing

在紧密配合土建、装修、暖通及电气中,本专业采取平行交叉施工,在工序上采取流水施工,在大的施工区域上流水施工,在局部平面和空间上采取立体交叉施工。In civil construction, renovation, HVAC, and water supply and drainage work closely with the

professional to take the parallel construction of cross-flow construction to take on in the process, the flow construction on a large construction area to take interchange construction on the local plane and space.

3.5施工管理措施 construction management measures

1)严格执行施工技术控制措施。对本专业的重要工序的质量控制方式,如隐蔽工程验收、

系统调整、系统模拟试验、单体试车等严格执行相关的技术管理程序文件充分保证施工质量。Strict implementation of the construction of technical control measures.

Professional quality control process, such as the hidden engineering. Experience Closing, system tuning, system simulation test, single test, strict implementation of the

technology management program files to fully guarantee the quality of construction.

2)加强图纸会审和技术交底控制措施。组织本专业图纸会审,重点解决施工接口管理

和技术管理人员对系统的熟悉,及时发现问题寻找解决办法,以避免返工对质量造成的影响。班组施工前, 规定施工技术交底的程序,以确保对每个施工人员进行技术质量控制。Strengthen drawings reviewing and technical tests, control measures.

Organization the professional drawings reviewing, focused on solving the familiar

construction interface management and technical management of the system, and to

discover the problem to find a solution to avoid rework impact on quality. Before the

construction of the team, the provisions of the construction of technical tests,

procedures, and technical quality control to ensure that each construction workers.

3) 加强施工现场文件的管理strengthen the management of the construction site files

(1) 指定专人负责现场文件的领发、登记、借阅、保管、回收、整理等管理工作;Designate

a person responsible for the site documentation, registration, lending, custody, recovery, finishing management;

(2)发生设计变更后应及时发放,做好发放登记签字手续。工程技术人员应及时对原设

计图纸 进行变更修改或做出更改标识,以便识别跟踪;Design changes should be

timely disbursement of do the formalities of issuing registration signature. Engineering

and technical personnel in a timely manner of the original. Design drawings change to

modify or make changes to the logo, in order to identify the track;

(3)施工一线的施工图纸、设计变更由施工班组长负责保管、使用、回收。Construction of

the front line of construction drawings, design changes by the construction team leader responsible for the custody, use, recycling.

4)加强员工培训管理Enhance staff training management

我们极重视对技术工人队伍的培训,定期开展技术工人岗位技能培训,解决施工中遇到的技术难题,不断提高自身的素质和能力。进入本工程施工的所有员工都必须进行施工质量、安全施工、文明施工、环境保护等要求的专项培训,只有经过专项培训的施工人员才可以进入施工现场作业。特种作业人员、特殊工作人员均需持证上岗。We attaché great importance to the training of skilled workers, and regularly carry out skilled workers, job skills training, to solve the technical problems encountered in the construction, and

constantly improve their own qualities and abilities. All employees into the construction must be the quality of construction, construction safety, civilized construction,

environmental protection and other requirements of special training, construction workers only after special training before they can enter the construction site operations. Special operations personnel, special staff required certificates.

5)坚持现场例会制度Adhere to the on-site system of regular meetings

(1)每周、月召开本专业工程例会,周工程例会在每周一晚上召开,月工程例会在每月

的最后一天的上午召开;例会由本专业工程师及施工工长主持;Arrange per week and per month regular meeting of the professional engineering, which shall begin at every

Monday night. The regular meeting will be chaired by the professional engineer and

construction foreman;

(2)工程例会上主要报告现场施工情况、存在的问题、汇总需协调的事宜、布置下一时

间的工作安排;Engineering regular meeting includes report on-site construction,

problems, summary of the matters to be coordinated and arranged the next time work

arrangements;

3.6施工技术准备 Construction technology preparation

工程技术准备阶段包括收集工程资料,详细研究工程项目、工程数量、工艺流程、工艺特点、质量标准、进度要求、图纸文件、设备订货、材料供应、土建装修进度基本情况,为进一步编制、修改施工方案、施工进度计划提供更准确的资料数据。组织专业人员熟悉图纸,对图纸进行自审, 熟悉和掌握施工图纸的全部内容和设计意图,解决好图纸及现场存在的问题。对机电安装专业之 间、土建及其他专业图纸相互蒙版对照,若发现问题,提前与建设单位、设计单位协商。The engineering preparation phase includes collecting engineering data, a detailed study of the project, the quantity of works, process, process characteristics, quality standards, schedule requirements, drawing files, equipment orders, material supply, construction decoration, the progress of the

basic situation, to further develop, modify construction the progress of the plan,

construction plan to provide more accurate information and data. Organize professionals who are familiar with the drawings, the drawings from the trial, to be familiar with and

master the entire contents of the construction drawings and design intent, to solve the

existing problems of drawings and on-site. If any problem is found, inform in advance the construction unit, designed in consultation with each other between the mechanical and electrical installation professional, civil engineering and other professional drawings Mask.

1)参加由建设单位、设计单位和监理单位组织的设计交底和图纸综合会审。It will be

participated in the tests, and drawings by the design of the construction units,

design units and supervision units integrated triage.

2)编制施工方案,送总工程师审批,并送交建设单位、监理单位审核,批准。Preparation

of the construction program, and be sent to the chief engineer for approval and sent to the construction units, supervision units audit approval.

3)了解土建的施工进度,以便具有针对性的编制科学合理的施工进度计划,了解土建

封闭管井及砌墙、批灰时间,以便配合土建的进度。Understand the progress of civil construction, in order to make targeted establishment of a scientific and reasonable

construction schedule, understanding of civil engineering closed tube wells and the

drywall i time, in order to match the progress of civil engineering.

4)做好技术交底工作。本专业工序开工前应对施工人员进行技术交底,技术交底是施

工企业技术管理的一个重要制度,是保证工程质量的重要因素,其目的是通过技术交底使参加施工的所有人员对工程技术要求做到心中有数,以便科学地组织施工和按合理的工序、工艺进行施工。专业技术交底均采用三级制,即项目部技术负责人→专业工长→各班组长。交底内容按系统交底包括施工图纸、技术资料、工艺流程、技术关键部位、质量标准、施工程序、进度要求、安全措施、新工艺、新操作方法以及现场情况等。工长接受后,应反复详细地向作业班组进行交底,班组长在接受交底后,应组织工人对照作业指导书进行认真讨论,全面理解施工意图,确保工程的质量和进度。Provide good technical disclosure. Construction personnel respond to the professional process started technical tests, technical tests, is an important system in the management of construction enterprises, an important factor to guarantee the

quality of the project, its purpose is technical disclosure of all persons to participate in the construction of engineering and technical requirements do aware of in order to

scientifically organize the construction of construction and reasonable process.

Professional technical tests, the three-tier system, the technical director of the project department → professional foreman → group leaders. Tests, the contents of system tests, including construction drawings, technical data, process, technology, key parts,

quality standards, construction procedures, schedule requirements, security measures, new technology, new operating methods, and site conditions. Foreman accepted, should be repeated in detail to the operational teams correspondent, group leaders in accept handover, should organize workers control work instructions seriously discuss a

comprehensive understanding of the construction intent to ensure the quality and

progress of the project.

3.7施工器具设备Construction machinery equipment

根据施工进度计划和劳动力组织计划合理配备施工机具设备,并对机具设备的安全状况、功能状况、环保状况进行检测、检查和发放使用许可证。对已超期服役的设备不能纳入施工设备计划里。According to the construction schedule and labor organizations plan is reasonable with construction machinery equipment, and machinery and equipment safety status, functional status, and environmental status of testing, inspection and issuance of the use permit. Extended service equipment can not be included in the plan of

construction equipment.

本专业主要使用的器具:

equipments for this construction

3.8工程施工协调 construction coordination

3.8.1与业主方的协调Owner coordination

1)我们将绝对服从业主方的管理。积极配合业主方进行场内的施工准备工作,为业主方排忧解难。随工程的进展及时调整施工进度计划密切配合业主方进行设备,材料的报审、交接和检验工作。We will absolutely obey the management of the owner. Actively cooperate with the Owner site construction preparation work to solve problems for the owner. Handover and inspection of equipment, material examination should be done closely with the owner to adjust the construction schedule with the progress of the project in a timely manner.

2)积极协助业主方进行设备选型,工程设计及安装配合工作,以满足各种设施功能的需要,并根据工程需要配备专业调试技术人员,确保工程如期投入使用。We will actively assist owners to make equipment selection, engineering design and installation work together to meet the needs of the various facilities function, according to project needs with professional commissioning and technical personnel, to ensure that the project schedule and put into use.

3)积极配合业主方进行工程修改,方案确定,技术论证,从业主方的角度出发,提出材料代用建议,并进行合理的经济分析,直到发包方满意为止,同时绝不借故小修小改拖延工期。We will actively cooperate with the owner to carry out the works to modify the program to determine the technical feasibility studies, starting from the

point of view of the Owner and recommending material substitution, and providing reasonable economic analysis, while by no means making excuses for a minor adjustment to delay construction period until the satisfaction of the Employer. 4)如果发生工程进度滞后于计划进度的情况,我们将积极组织施工人员进场并实行加班,加点等赶工措施,确保本专业工程按期竣工。If the project is behind schedule, we will actively organize construction workers to approach for the implementation overtime, and take acceleration measures to ensure that the project is on schedule for completion of the professional.

5)工程施工中,我们将至始至终站在业主方的立场上,切实从舒适,操作方便,便于维修的角度进行施工,为发业主提供最好的服务。In the process of construction, we will be at top standing position of the owners' side, effectively be constructed from a comfortable, easy to operate, easy for maintenance point of view, and provide the best service for the owners.

6)和业主方一起做好施工场地地下管线,方物和领近建筑物,构筑物,古树名木的保护工作Together with the owner, do underground pipeline at the construction site, and the protection of buildings, structures, trees, square things and collar nearly. 3.8.2与各专业协调 with the professional coordination

1)在与装饰配合时,积极做好工序安排,在按设计做好隐蔽验收的基础上交付装饰单位,并在施工中仔细复核标高,尺寸,及时报告监理,绝不损坏装饰产品。When collaborating with decorative work, actively carry out work arrangements, decoration units delivered based on design well hidden acceptance levels, dimensions, and carefully review the construction, and timely report of supervision. no damaged decorative products is accepted. It is necessary to strictly control access to construction personnel entering the installation splice.

2)在精装修进入安装镶接阶段时要严格控制出入施工人员,进行登记出入证管理,减少损坏因素,保证装饰产品整洁。When in fine decoration phase, registration passes Management, and reduces damage factors to ensure the cleanliness of the decorative products.

3)对需要留检查孔,检查口的地方,在装饰施工之前,及时通知装饰单位;说明吊顶留孔的位置及尺寸大小,以便于装饰单位施工。If there is any need for the

inspection of certain holes, check the mouth before decoration construction promptly notify decoration units; the ceiling remains the position of the hole and the size, in order to facilitate the construction of decorative units.

4)作好产品的保护工作,对自己安装的设备及器具要进行封闭管理,如配电柜等。Provide for the protection of the product, and want to install their own equipment and appliances will be closed management, such as the distribution cabinet.

3.9材料设备进场计划:Materials and equipment site entering plan:

第四章 施工方案construction program

本公司技术部在接到该工程招标文件、施工图纸后,根据工程现场实际情况,经有关专业技术人员认真分析、研究;针对该工程设有火灾自动报警及联动控制系统、自动喷水灭火系统、室内消火栓给水系统,特制订本施工方案,做为工程施工依据,具体技术方案如下:Our technical department in receipt of the project tender documents, construction drawings, according to the actual situation of the project site by the relevant professional and technical personnel, careful analysis, research;

sprinkler system with automatic fire alarm and linkage control system for the project,

fire hydrant water supply system, especially the development of the construction

program, as the basis for construction, specific technical programs are as follows:

4.1 火灾自动报警及联动控制系统Automatic fire alarm

and linkage control system

(1).施工工艺流程Construction process 深化图纸 →管道、线槽敷设→线、缆敷设→校接线及绝缘电阻测试→

设备安装→单机调试→系统调试→验收。

Construction preparation →Deepening the drawing→ pipes and trucking laying →

line, cable laying wiring and insulation resistance test→ installation → stand-alone

debugging → debug → acceptance.

(2).主要分项工程施工方法及技术要求

Major sub engineering construction methods and technical requirements

1)布线 laying lines

1.在管内或线槽内的穿线,应在建筑抹灰及地面工程结束后进行。在穿线前,

应将管内或线槽内的积水及杂物清除干净,有利于穿线后提高线路的绝缘电阻,在

穿线时,必须使用护围,以保护导线绝缘层。Threading pipe or duct, should be

conducted after the end of the building plaster and ground engineering. Before

threading the stagnant water and debris, should pipe or duct clean, help to improve

the insulation resistance of the line threading, threading, you must use guards to

protect the wire insulation.

2.火灾自动报警系统应单独布线,系统内不同电压等级、不同电流类别的线路,

不应穿在同一管内或线槽的同一槽孔内。 Automatic fire alarm system should be

routed separately, different voltage levels within the system, different categories of

current lines, should not be worn in the same slot on the same tube or trunking.

3.导线在管内或线槽内,不应有接头或扭结。导线的接头,应在接线盒内焊

接或用端子连接。3. Wire connectors or kinks in the pipe or duct should not. Wire

connector in the terminal box welded or connected to the terminal.

4. 敷设在多尘或潮湿场所管路的管口和管子连接处,均应作密封处理。穿越人

防防护墙或临空墙处,应按规范要求做好密闭处理。 Lay in dusty or humid places

piping nozzle and pipe connections should be sealed. Through the civil air defense

protective wall or at the free wall and closed processing specifications should be asked

to do a good job.

5.管路超过下列长度时,应在便于接线处装设接线盒:

Pipe over the following lengths should be installed at the ease of wiring junction box:

5.1 管子长度每超过30m,无弯曲时;

5.2 管子长度每超过20m,有1个弯曲时;

5.3 管子长度每超过15m,有2个弯曲时;

5.4 管子长度每超过8m,有3个弯曲时。

5.1 tube length of more than 30m without bending;

5.2 The length of the tube each more than 20m, a bending;

5.3 The length of the tube each more than 15m, the bending of the two;

5.4 per tube length over 8m, there are three bent.

6. 金属管子入盒时,盒外侧应套锁母,内侧应装护口,在吊顶内敷设时,盒的

内外侧均应套锁母。在吊顶内敷设各类管路和线槽时,宜采用单独的卡具吊装或支

撑物固定。Metal tube into the box, outside of the box should be set lock nut should be

installed inside the mouth care, laying in the ceiling, inside and outside of the box

should be set to the lock nut. Laying of various types of pipe and duct in the ceiling,

should adopt a separate fixture lifting or support fixed.

7. 线槽的直线段应每隔1.0~1.5 m设置吊点或支点,在下列部位也应设置吊点

或支点: The trough line segment should be set at intervals of 1.0 to 1.5 m hanging

point or fulcrum, should also be set hanging point or fulcrum of the following areas:

7.1线槽始端、终端及接头处;

7.2 距接线盒0.2 m处;

7.3 线槽走向改变或转角处,应采用防晃吊架。

7.1 trucking start and end points and joints;

7.2 at 0.2 m from the junction box;

7.3 trucking to the change or the corner should be used in anti-shake hanger.

8. 吊装线槽的吊杆直径,不应小于6mm 。Boom lifting trough diameter should

not be less than 6mm.

9. 管线经过建筑物的变形缝(包括沉降缝、伸缩缝、抗震缝等)处,应采取补

偿措施,导线跨越变形缝的两侧应固定,并留有适当余量。

Pipeline after building deformation joint (including settlement joint, expansion joints, seismic joints), should take compensatory measures, leads across both sides of the deformation joint should be fixed and leave appropriate margin.

10.火灾自动报警系统导线敷设后,应对每回路的导线用500V的兆欧表测量绝

缘电阻,其对地绝缘电阻值不应小于20MΩ。 automatic fire alarm system wire laying response to each loop wire 500V megger to measure the insulation resistance of the insulation resistance value should not be less than 20M.

2)火灾探测器的安装installation of fire detectors

1. 点型火灾探测器的安装位置,应符合下列规定:

1.1 探测器至墙壁、梁边的水平距离,不应小于0.5m 。

1.2 探测器周围0.5m内,不应有遮挡物。

1. The installation location of the point-type fire detectors shall comply with the

following requirements:

1.1 detector to the wall, the horizontal distance of the beam edge, should not be less than 0.5m.

1.2 around the detector 0.5m, there should be no obstacles.

1.3 探测器至空调送风口边的水平距离,不应小于1.5m;至多孔送风顶棚孔

口的水平距离,不应小于0.5m。The detector to air conditioning send the outlet side of the horizontal distance should not be less than 1.5m; opening to the the porous air supply ceiling horizontal distance should not be less than 0.5m.

1.4 在宽度小于3 m的内走道顶棚上设置探测器时,宜居中布置。点型感温

探测器的安装间距,不应超过10 m;点型感烟探测器的安装间距,不应超过15 m。探测器距端墙的距离,不应大于探测器安装间距的一半。

Set within the aisle width of less than 3 m ceiling detector should be centrally disposed. Point type heat detector installation spacing should not exceed 10 m; point type smoke detector installation spacing should not exceed 15 m. The detector distance away from the end wall should not be greater than half of the detector spacing.

1.5 探测器宜水平安装,当必须倾斜安装时倾斜角不应大于45°。The detector

should be mounted horizontally, the tilt angle should not be greater than 45 ° must tilt the installation.

2. 线型火灾探测器和可燃气体探测器等有特殊安装要求的探测器,应符合现行

有关国家标准的规定。The linear fire detectors and combustible gas detectors and other special installation requirements detectors, shall comply with the provisions of the existing national standards.

3. 探测器的底座应固定牢靠,其导线连接必须可靠压接或焊接,当采用焊接时,

不得使用带腐蚀性的助焊剂。Detector base shall be fixed firmly to the wire

connections must be reliable crimping or welding, when the use of welding may not be used with corrosive flux.

4. 同一工程中的导线,应根据不同用途选不同颜色加以区分,相同用途的导线

颜色应一致。电源线正极应为红色,负极应为蓝色或黑色。 The wires in the same project should be selected according to the different uses different colors to

distinguish between the same purpose wire colors should be consistent. The positive electrode of the power cord should be red; the negative electrode should be blue or black.

5. 探测器底座的外接导线,应留有不小于15cm的余量,入端处应有明显标志。

External conductor of the detector base should be left a margin of not less than 15 cm into the end should be clearly marked.

6. 探测器底座的穿线孔宜封堵,安装完毕后的探测器底座应采取保护措施。

Detector base threading hole should be plugging After installation of the detector base should take protective measures.

7. 探测器的确认灯,应面向便于人员观察的主要入口方向。Detector Ensure that

the lamp should be oriented to facilitate the direction of the main entrance of the observed.

8. 探测器在即将调试时方可安装,在安装前应妥善保管,并应采取防尘,防潮,

防腐蚀措施。Detector be installed in the upcoming commissioning, installation should be properly safeguarded and that should be taken to dust, moisture, anti-corrosion measures.

3) 手动火灾报警按钮的安装 hand fire alarm button installation

1. 手动火灾报警按钮,当安装在墙上时,其底边距地(楼)面高度宜为 1.3~

1.5m。Manual fire alarm button, when mounted on the wall, the bottom margin (floor) surface height should be 1.3 ~ 1.5m.

2.手动火灾报警按钮,应安装牢固,并不得倾斜。Manual fire alarm button should

be securely installed, and not tilted.

3.手动火灾报警按钮的外接导线,应留有不小于15cm的余量,且在其端部应

有明显标志。The external conductor of the manual fire alarm button, should allow a margin of not less than 15cm, and should be clearly marked on its end portion.

4) 火灾报警控制器的安装fire alarm controlling equipment installation.

1. 火灾报警控制器(以下简称控制器)在墙上安装时,其底边距地(楼)面高

度宜为1.3~1.5m;落地安装时,其底边宜高出地坪0.1~0.2 m。When the fire alarm controlling machine (controlling machine for short) is installed, the elevation should be

1.3~1.5m; when it is being installed, the elevation should be 0.1~0.2 m.

2. 控制器应安装牢固,不得倾斜。安装在轻质墙上时,应采取加固措施。The

controlling machine should be installed firmly, without any deviation when it is

installed on the light weight wall, relevant measures should be taken for fixation.

3. 引入控制器的电缆或导线,应符合下列要求:the cables that are connected

into the controlling equipment should follow the relevant requirements;

3.1 配线应整齐,避免交叉,并应固定牢靠;all the lines should be even, and no

crossing is allowed, which should be fixed firmly;

3.2 电缆芯线和所配导线的端部,均应标明编号,并与图纸一致,字迹清晰,

不易退色。The end of the cables and lines should be marked clearly, and be in line with the drawings and in clearing bold.

3.3 端子板的每个接线端,接线不得超过2根;the connecting lines should be

no more than 2 for each connecting end.

3.4 电缆芯和导线,应留有不小于20cm的余量;Leave at least 20cm for the

cables and lines.

3.5 导线应绑扎成束;The lines should be tied and arranged.

3.6 导线引入线穿线后,在进线管处应封堵。Inlet pipe should be blocked after

the lining.

4. 控制器的主电源引入线,应直接与消防电源连接,严禁使用电源插头。主电

源应有明显标志。Main power line of the controlling equipment should be connected by the fire fighting power and it is strictly forbidden to use any power socket. The main power should be clearly marked.

5. 控制器的接地、应牢固,并有明显标志。The controlling equipments should be

grounded firmly, with a clear mark.

5)消防控制设备的安装 firefighting equipment installation

1.消防控制设备在安装前,应进行功能检查,不合格者,不得安装。Before the

firefighting equipment installation begins, check all the functions and if any defects found, that equipment should be removed.

2.消防控制设备的外接导线,当采用金属软管作套管时,其长度不宜大于2m,

且应采用管卡固定,其固定点间距不应大于0.5m。金属软管与消防控制设备的接线盒(箱),应采用锁母固定,并应根据配管规定接地。Adopt Metal hose as casing for the external conductors of the firefighting controlling equipment, the length of which should be no larger than 2m, and fixed by pipe card, the spacing between which should be no larger than 0.5m. the connecting box of the Metal hose and the

firefighting controlling equipment should be fixed and grounded according to the rules.

3.消防控制设备外接导线的端部,应有明显标志。The end of the firefighting

controlling equipment

4.消防控制设备盘(柜)内不同电压等级,不同电流类别的端子,应分开,并

有明显标志。

6)系统接地装置的安装 system grounded equipment installation

1.工作接地线应采用铜芯绝缘导线或电缆,不得利用镀锌扁铁或金属软管。

Work grounding wire should be insulated copper wire or cable, must not use

galvanized flat iron or metal hose.

2.由消防控制室引至接地体的工作接地线,在通过墙壁时,应穿入钢管或其它

坚固的保护管。The work grounded line that is introduced from the firefighting

controlling room to the grounded area, should be added by steel pipe or other firm protective pipe.

3.工作接地线与保护接地线,必须分开,保护接地导体不得利用金属软管。The

work grounded line should be separated from the protective the grounded line, and the protective conductor should not use Metal hose.

4.接地装置施工完毕后,应及时作隐蔽工程验收。验收应包括下列内容:after the

grounded installation has been finished, the hidden work inspection and acceptance should be conducted in a timely manner. It should include the following items:

4.1 测量接地电阻,并作好记录;Check and keep record of the grounded

resistance.

4.2 查验应提交的技术文件;Technical document submittal inspection

4.3 审查施工质量。Construction quality inspection

7)系统的调试 system debugging

1.一般规定 general rules

1.1 火灾自动报警系统的调试,应在系统施工结束后进行。The commissioning

of automatic fire alarming system should be conducted after the construction has been completed.

1.2 火灾自动报警系统调试前应具备施工及验收规范中规定的所列文件与调

试必需的其它文件。The automatic fire alarming system debugging should be

equipped with relevant documents specified in the construction regulations and other documents that are needed in the processing of debugging.

1.3 调试负责人必须由有资格的专业技术人员担任,所有参加调试人员应职

责明确,并应按照调试程序工作。The debugging should be conducted by

professionals who hold relevant certificates. All the workers involved should

understand their responsibilities and proceed according to the debugging procedures.

2.调试前的准备 preliminary work before the debugging.

2.1设备的规格、型号、数量、备品备件等应按设计要求查验。All the

specifications, types, quantities and other items of the equipment should be checked according to the design requirements.

2.2 应按施工及验收规范要求检查系统的施工质量。对属于施工中出现的问

题,应会同有关单位协商解决,并有文字记录。Check the construction quality of the system according to the construction and acceptance regulations. If any defects found

in the construction process, coordinate with relevant institutes and keep record of that.

2.3 应按施工及验收规范要求检查系统线路,对于错线、开路、虚焊和短路

等应进行处理。Check the system and all the lines according to the construction and acceptance regulations. All the shortcuts and other problems should be dealt in a timely manner.

2.4 对系统中的火灾报警控制器、消防联动控制器、气体灭火控制器、消防电

气控制装置、消防设备应急电源、消防应急广播设备、消防电话、传输设备、消防电动装置、区域显示器(火灾显示盘)、消防应急灯具控制装置、火灾警报装置等设备分别进行单机通电检查。Check individually with electricity all the fire alarm controlling equipment, fire linkage controller, gas fire extinguishing controller, fire, electrical controls, emergency power supply of fire-fighting equipment, fire emergency broadcasting equipment, fire telephone transmission equipment, firefighting

electrical devices, regional display (fire display panel), fire emergency lighting control devices, fire alarms, etc, of the system.

3.火灾报警控制器调试 automatic fire alarming system commissioning

3.1调试前应切断火灾报警控制器的所有外部控制连线,并将任一个总线回路

的火灾探测器以及该总线回路上的手动火灾报警按钮等部件连接后,方可接通电源。Before debugging, cut off all external control connections of the fire alarm

controlling equipments, and he was a bus loop fire detectors and bus loop and other parts of the manual fire alarm button connected prior to turning on the power.

3.2按现行国家标准《火灾报警控制器》GB 4717 的有关要求对控制器进行下

列功能检查并记录,控制器应满足标准要求:Check and keep record of the functions of the controlling equipment in comply with current national standard "fire alarm controller with the relevant requirements of GB 471, and the controller should meet the standards:

1 检查自检功能和操作级别; Check the self-testing functions and operations

level;

2 使控制器与探测器之间的连线断路和短路,控制器应在 100s 内发出故障

信号(短路时发出火灾报警信号除外);在故障状态下,使任一非故障部位的探测

器发出火灾报警信号,控制器应在 1min内发出火灾报警信号,并应记录火灾报警时间;再使其他探测器发出火灾报警信号,检查控制器的再次报警功能; Cut off the connection between the controller and the detector circuit, and the controller should a fault (short circuit issue except for the fire alarm signal); issued under fault conditions, so that any non-faulty portion of the detector 100s a fire alarm signal, the controller should be issued within 1min fire alarm signal, and shall record the time of the fire

alarm; other detector sends a fire alarm signal, check the controller's alarm function again

3 检查消音和复位功能; Check the silencer and reset functions;

4 使控制器与备用电源之间的连线断路和短路,控制器应在 100s 内发出故

障信号; Cut off the connection between the controller and the detector circuit and the controller should a fault (short circuit issue except for the fire alarm signal

5 检查屏蔽功能; Check and hidden functioning

6 使总线隔离器保护范围内的任一点短路,检查总线隔离器的隔离保护功

能; Isolate the main line at any point within the scope of the protection short circuit, check the bus isolator isolation protection function;

7 使任一总线回路上不少于 10 只的火灾探测器同时处于火灾报警状态,

检查控制器的负载功能; Make sure that any main line will be less than 10 fire

detectors and fire alarm mode check the controller's load function;

8 检查主、备电源的自动转换功能,并在备电工作状态下重复第 7 款检查;

Check the main and backup power automatic conversion and repeat, paragraph 7,

check the backup power state;

9 检查控制器特有的其他功能。 Check that the controller-specific functions.

3.3 依次将其他回路与火灾报警控制器相连接,重复 4.3.2中 2、6、7 项检查。

connect other circuit and fire alarm controller, repeat the 2,6,7 inspection 4.3.2

4. 消防联动控制器调试 fire linkage controller debugging

4.1 将消防联动控制器与火灾报警控制器、任一回路的输入/输出模块及该回路

模块控制的受控设备相连接,切断所有受控现场设备的控制连线,接通电源。 Fire linkage controller and fire alarm controller, connected to any circuit input / output

modules control the controlled device and the circuit module, cut off all controlled

field device control connections, turn on the power.

4.2 按现行国家标准《消防联动控制系统》GB16806 的有关规定检查消防联动

控制系统内各类用电设备的各项控制、接收反馈信号(可模拟现场设备启动信号)和显示功能。 At the current national standards for fire protection control system

"GB16806 relevant provisions of inspection of fire linkage control system within the control of various types of electrical equipment, receive feedback signal (analog field devices start signal) and display functions.

4.3 使消防联动控制器分别处于自动工作和手动工作状态, 检查其状态显示,

并按现行国家标准《消防联动控制系统》GB16806 的有关规定进行下列功能检查并记录,控制器应满足相应要求: Make the fire linkage controller in automatic

operation and manual work status, check its status, in accordance with current

national standard "for fire protection control system with the relevant provisions of GB16806 following functions Check and record the controller should meet the

requirements:

1 自检功能和操作级别。 Self-testing function and operational level.

2 消防联动控制器与各模块之间的连线断路和短路时,消防联动控制器能在

100s秒内发出故障信号。 Fire linkage controller and module connection open and short circuits, fire linkage controller in the 100s seconds a fault signal.

3 消防联动控制器与备用电源之间的连线断路和短路时,消防联动控制器应

能在 100s内发出故障信号。 Fire linkage controller with standby power between the connection open and short circuits, fire linkage controller should be able to issue in the 100s fault signal.

4 检查消音、复位功能。Check the silencer, reset function.

5 检查屏蔽功能。 Check the shielding function.

6 使总线隔离器保护范围内的任一点短路,检查总线隔离器的隔离保护功能。

Isolate the main line any point within the scope of the protection short circuit, check the bus isolator isolation protection function.

7 使至少 50 个输入/输出模块同时处于动作状态(模块总数少于 50 个时,使

所有模块动作),检查消防联动控制器的最大负载功能。 at least 50 input / output modules in action at the same time (the total number of modules is less than 50, so

that the action of all modules), check the maximum load of the fire linkage controller function.

8 检查主、备电源的自动转换功能,并在备电工作状态下重复第 7 款检查。

Check the main and backup power automatic conversion and repeat, paragraph 7,

check the backup power state.

4.4 接通所有启动后可以恢复的受控现场设备。Switching controlled field devices

can be restored after the start.

4.5 使消防联动控制器的工作状态处于自动状态,按现行国家标准《消防联动

控制系统》GB16806的有关规定和设计的联动逻辑关系进行下列功能检查并记录: the working status of the fire linkage controller is in automatic state, according to the current national standard "fire control system" the linked logical relationship of the relevant provisions of GB16806 and design the following functions Check and record: 1 按设计的联动逻辑关系,使相应的火灾探测器发出火灾报警信号,检查消

防联动控制器接收火灾报警信号情况、发出联动信号情况、模块动作情况、受控设备的动作情况、受控现场设备动作情况、接收反馈信号(对于启动后不能恢复的受控现场设备,可模拟现场设备启动反馈信号)及各种显示情况; the linkage logical relationship of the design, so that the corresponding fire detectors a fire alarm signal, check the fire linkage controller receives the fire alarm signal issued linkage signal of the module action, the action of the controlled device, controlled field devices action, receive feedback signal (can not be restored after the start controlled field devices,

analog field devices to start the feedback signal) and a variety of display case;

2 检查手动插入优先功能。 Check manually insert priority function.

4.6 使消防联动控制器的工作状态处于手动状态,按现行国家标准《消防联动

控制系统》GB16806的有关规定和设计的联动逻辑关系依次手动启动相应的受控设备,检查消防联动控制器发出联动信号情况、模块动作情况、受控设备的动作情况、受控现场设备动作情况、接收反馈信号(对于启动后不能恢复的受控现场设备,可模拟现场设备启动反馈信号)及各种显示情况。 the working status of the fire

linkage controller is in manual mode, the current national standard "fire linkage control system" the linked logical relationship of the relevant provisions of GB16806 and

design in turn started manually controlled equipment, inspection of fire linkage

controller issue linkage signal case, the module action, the controlled device action, controlled field device action, receiving the feedback signal (controlled field devices can not be restored after the start, you can start the feedback signal analog field

devices) and a variety of display case.

4.7 对于直接用火灾探测器作为触发器件的自动灭火控制系统除符合本节有关

规定外, 尚应按现行国家标准《火灾自动报警系统设计规范》GB 50116 规定进行功能检查。 for the direct use of fire detectors as triggering automatic fire

extinguishing control system in addition to complying with the relevant provisions of this section is still in accordance with the existing national standard automatic fire

alarm system design "GB 50116 provides for the functional check.

5.火灾自动报警系统的系统性能调试Automatic fire alarm system, system

performance debugging

5.1 将所有经调试合格的各项设备、系统按设计连接组成完整的火灾自动报警

系统,按《火灾自动报警系统设计规范》GB 50116 和设计的联动逻辑关系检查系统的各项功能。 All passing through the commissioning of the equipment, the system is designed to connect to form a complete automatic fire alarm system, automatic fire alarm system design specifications of GB 50116 and design linkage logical relationships inspection system of the function.

5.2 火灾自动报警系统在连续运行 120h 无故障后,按规范规定填写调试记录

表。Automatic fire alarm system should work in continuous operation 120h without failure, according to the specification fill in the debug log table.

施工难点分析:Construction difficulties analysis

消防系统设计专业多,各专业之间图纸问题、各单位之间配合问题。Too many fire protection system design professional, among the professional drawings between the various units with the problem.

火灾报警联动设备要尽快定型,不同厂方设备在线路敷设和施工要求上有不同要求。 装修问题:装修与否、吊顶高度、顶棚布置、装修材料等。

Fire alarm equipment as soon as possible stereotypes, have different requirements in different factory equipment on the line laying and construction requirements. Of decoration: decoration or not, ceiling height, ceiling decoration, decoration materials.

设计人员应明确各消防联动设备的启动条件和控制方式。The designer should be clear of the fire linkage equipment start-up conditions and controlling methods.

4.2 自动喷水灭火喷淋系统 Automatic sprinkling fire extinguishing system

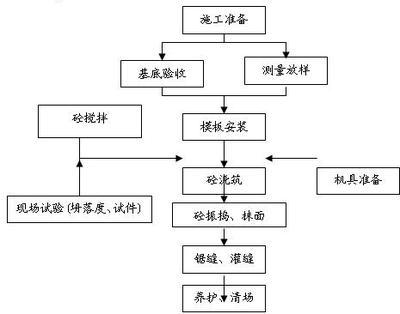

一、施工工艺流程:construction flow

施工准备→管网及系统组件安装→系统试压和冲洗→系统调试。

Construction preparation → pipe network and system components installation → System pressure test and flushing → system debugging.

二、系统施工准备 system construction preparation

1.自动喷水灭火系统施工前应对采用的系统组件、管件及其他设备、材料进行现场检查,并应符合下列要求:Automatic sprinkler the cope with used in in the the pre-construction of the fire extinguishing system components, pipe fittings, and other equipment,

1.1系统组件、管件及其他设备、材料,应符合设计要求和国家现行有关标准的规定,并应出具出厂合格证;system components, pipe fittings, and other equipment, materials, should be consistent with the design requirements and the in force in the country the the provisions of of the the relevant standards, and should be issued by the factory certificate;

1.2喷头、报警阀、压力开关、水流指示器等主要系统组件应经国家消防产品质量监督检验中心检测合格。Major system components of the 1.2 nozzle, alarm valve, pressure switch, water flow indicator and so on is shall be approved by the the detection of qualified of the National Fire Protection product quality Supervision and Inspection Center.

2.管材、管件应进行现场外观检查,并应符合下列要求:Pipe materials, pipe fittings

should be carried out site the appearance of and inspection, and should meet the the the following requirements:

2.1表面应无裂纹、缩孔、夹渣、折迭和重皮;The surface should be free of cracks, shrinkage, slag, folding and double skin;

2.2螺纹密封面应完整、无损伤、无毛刺;thread sealing surface should be complete, no damage, no glitches;

2.3镀锌钢管内外表面的镀锌层不得有脱落,锈蚀等现象; The the galvanized layer of the 2.3 galvanized steel pipe the inner and outer surfaces of shall not be there are fall off, corrosion and other phenomena;

2.4非金属密封垫片应质地柔韧、无老化变质或分层现象,表面应无折损,皱纹等缺陷;Non-metallic sealing gasket should be texture, flexibility, no aging

metamorphism or layered the phenomenon of and, the surface should be no folded, so the defects of the or wrinkle, or any such as a whole;

2.5法兰密封面应完整光洁,不得有毛刺及径向沟槽;螺纹法兰的螺纹应完整,无损伤。Flange sealing surface should provide a complete bright and clean, no has a burr on and radial grooves in charges shall be allowed; the the threaded of the threaded flange should provide a complete, no damage. 3.喷头的现场检验应符合下列要求:

sprinklers site inspection shall comply with the following requirements:

3.1喷头的型号、规格应符合设计要求;nozzle models, specifications should meet the design requirements;

3.2喷头的商标、型号、公称动作温度、制造厂及生产年月等标志应齐全;nozzle trademark, model, nominal operating temperature, the manufacturer and year of production and other signs should be complete;

3.3喷头外观应无加工缺陷和机械损伤;Nozzle appearance should be free of manufacturing defects and mechanical damage;

3.4喷头螺纹密封面应无伤痕,毛刺、缺丝或断丝的现象;Nozzle thread sealing surface of the phenomenon should be no scars, glitches, lack of wire or broken wire

3.5闭式喷头应进行密封性能试验,并以无渗漏、无损伤为合格,试验数量宜从每批中抽查1%,但不得少于5只,试验压力为3.0Mpa;试验时间不得少于3min。

当有两只及以上不合格时,不得使用该批喷头。当仅有一只不合格时,应再抽查2%,但不得少于10只。重新进行密封性能试验,当仍有不合格时,亦不得使用该批喷头。The closed nozzle sealing performance test, and no leakage, no damage is qualified, the number of tests should be spot checks from each batch of 1%, but it should be not less than five, the test pressure to 3.0 MPa; test time shall not be less than 3 minutes. May not be used when two or more failed batch nozzle. Only one failed should be spot checks 2%, but not less than 10. Re-sealing performance test, when still failed, nor to use for the nozzle.

4.阀门及其附件的现场检验应符合下列要求:the valves and the components site

inspection should follow the following requirements:

4.1 阀门的型号、规格应符合设计要求;the valves specifications and types should

meet design requirements;

4.2 阀门及其附件应配备齐全,不得有加工缺陷和机械损伤;Valves and accessories

should be fully equipped, may not have manufacturing defects and mechanical

damage;

4.3 报警阀除应有商标、型号、规格等标志外,尚应有水流方向的永久性标志; alarm

valve due trademarks, models, specifications and other signs, there should be a

permanent symbol of the direction of flow;

4.4报警阀和控制阀的阀瓣及操作机构应动作灵活,无卡涩现象;阀体内应清洁,

无异物堵塞; Alarm and control valves valve operating mechanism of action should be flexible, jam phenomenon; valve body should be clean, no blockage;

4.5 水力警铃的铃锤应转动灵活,无阻滞现象;

The water alarm bell Hammer rotating flexible, non-blocking phenomenon;

4.6报警阀应逐个进行渗漏试验,试验压力应为额定工作压力的2倍,试验时间

应为5min。阀瓣处应无渗漏。 Alarm valve should be individually tested for leakage test pressure shall be 2 times the rated working pressure, test time for 5 min. The valve should be no leakage.

5. 压力开关、水流指示器及水位,气压,阀门限位等自动监测装置应有清晰的铭

牌,安全操作指示标志和产品说明书;水流指示器尚应有水流方向的永久性标志;安装前应逐个进行主要功能检查,不合格者不得使用。 Pressure switch, water flow

indicator and water level, pressure, valve limit automatic monitoring devices should be clear nameplate, safe operation signs and product manuals before installation; flow indicator is still the direction of flow should be permanently marked; The main function tests one by one, the failure may not be used.

三.主要分项工程施工方法及技术要求

Major sub engineering construction methods and technical requirements

1.消防水泵接合器安装Fire pump adapter installation

1.1消防水泵接合器的组装应按接口、本体、联接管、止回阀、安全阀、放空管、

控制阀的顺序进行。止回阀的安装方向应使消防用水能从消防水泵接合器进入系统。Fire pump adapter assembly shall interface body, connecting tube, check valves, safety valves, vent pipe, control valve order. Check valve installation should be directed to the fire with water from the fire pump adapter into the system.

1.2 防水泵接合器的安装应符合下列要求:

Anti-pump adapter installation shall meet the following requirements:

1.2.1 应安装在便于消防车接近的人行道或非机动车行驶地段;it should be

installed on the sidewalks and non-motor vehicle with lots of easy to fire engines close;

1.2.2地下消防水泵接合器应采用铸有“消防水泵接合器”标志的铸铁井盖,并在

附近设置指示其位置的固定标志;Underground fire pump adapter should be used to cast iron manhole covers, cast of "fire pump adapter" signs indicate its location in the vicinity of the fixed signs;

1.2.3 地上消防水泵接合器应设置与消火栓区别的固定标志; ground fire pump

adapter should be set to the the fire hydrant difference between the fixed signs;

1.2.4墙壁消防水泵接合器的安装应符合设计要求。设计无要求时,其安装高度宜

为1.1m;与墙面上的门、窗、孔、洞的净距离不应小于2.0m,且不应安装在玻璃幕墙下方。wall fire pump adapter installation shall meet the design requirements. Design No installation height should be 1.1m; net wall, door, window, hole, hole

distance of not less than 2.0m, and should not be installed in the bottom of the glass curtain wall.

1.3地下消防水泵接合器的安装,应使进水口与井盖底面的距离不大于0.4m,且

不应小于井盖的半径。Underground fire pump adapter installation, the inlet and

covers the underside of the distance no greater than 0.4m, and should not be less than the radius of the covers.

1.4 地下消防水泵接合器井的砌筑应符合下列要求: Underground fire pump

adapter shall meet the following requirements:

1.4.1 在最高地下水位以下的地方设置地下消防水泵接合器井时,其井壁宜采用

Mu7.5级砖、M7.5级水泥砂浆砌筑,且井壁内、外表面应采用1:2水泥砂浆抹面,并应掺有防水剂,其抹面的厚度不应小于20mm,抹面高度应高出最高地下水位

250mm。当管道穿过井壁时,管道与井壁间的间隙宜采用粘土填塞密实,并应采用M7.5级水泥砂浆抹面,抹面厚度不应小于50mm。the underground fire pump adapter wells set in place the highest groundwater level, the borehole wall should

adopt level Mu7.5 brick M7.5-class cement mortar masonry, and the borehole wall, the outer surface should be used: 2 cement mortar surface, and should be mixed with water repellent, wipe the surface thickness of not less than 20mm, wipe the surface height should be higher than the highest groundwater level 250mm. When the pipeline through the borehole wall, the gap between the pipe and the borehole wall should adopt the clay packing dense, and should be used M7.5 cement mortar surface, wipe the surface thickness of not less than 50mm.

2.管网安装Pipe network installation

2.1管道安装时使用符合安全要求的移动脚手架,在上较长管道时使用俩付脚手

架用绳索固定管俩边并水平拉起。during the installation of the pipe with the

mobile scaffolding safety requirements, in the longer pipeline using both pay the scaffolding fixed tube both sides and pull rope.

2.2管网安装前应校直管子,并应清除管子内部的杂物;安装时应随时清除已安

装管道内部的杂物。Network installation before straightening the tube, and should be cleared of debris inside the tube; installed inside the pipes should be installed at any time to remove debris.

2.3 在具有腐蚀性的场所安装管网前,应按设计要求对管子、管件等进行防腐处

理。Network installation before straightening the tube, and should be cleared of debris inside the tube; installed inside the pipes should be installed at any time to remove debris.

2.4管道连接后不应减小过水横断面面积。热镀锌钢管安装应采用螺纹、 沟槽式

管件或法兰连接(实际施工时,根据设计文件选用)。Water cross-sectional area of the pipe connections should not be reduced. Hot galvanized steel pipe shall be

installed using threaded, grooved fittings or flange connection (the actual construction, selected according to the design documents).

2.5 螺纹连接应符合下列

要求:Threaded connections

shall comply with the

following requirements:

2.51管子宜采用机械切割,

切割面不得有飞边、毛刺;

管子螺纹密封面应符合现行

国家标准《普通螺纹基本尺

寸要求》、《普通螺纹公差

与配合》、《管路旋入端用

普通螺纹尺寸系列》的有关

规定;tubes should adopt the mechanical cutting, cutting surface without flash, burrs; pipe thread sealing surface should be consistent with the current national standard "common thread size requirements, the common thread tolerance and fit", "pipe into the end with the relevant provisions of the common thread Size series;

2.5.2当管道变径时,宜采用异径接头;在管道弯头处不得采用补芯;当需要采用

补芯时,三通上可要1个,四通上不应超过2个;公称直径大于50mm的管道,不宜采用活接头;When the pipe is adjustable, reducers should be adopted; shall not be used at the pipe elbow bushing; happen one when the need to complement the core, three, four-way should not be more than two; nominal greater than 50mm in diameter pipes, wood joints should not be used;

2.5.3螺纹连接的密封填料应均匀附着在管道的螺纹部分;拧紧螺纹时,不得将填

料挤入管道内;连接后,应将连接处外部清理干净。Screwed gland packing should be evenly attached to the threaded portion of the pipe; tighten the thread, not squeeze into the filler pipe; connect external connections should be clean up.

2.6管道的安装位置应符合设计要求,当设计无要求时,管道的中心线与梁、

柱、楼板等的最小距离应符合下表规定。The pipeline installation location should meet the design requirements, the centerline of the pipe and beams, columns, floors, etc. The minimum distance should meet the following requirements when the design has no requirements.

管道的中心线与梁、柱、楼板的最小距离

The centerline of the pipe with the minimum distance of the beams, columns, slabs

2.7 管道支架、吊架、防晃支架的安装应符合下列要求:

2.7.1管道应固定牢固;管道支架或吊架之间的距离不应大于下表规定

2.7.2管道支架、吊架、防晃支架的型式、材质、加工尺寸及焊接质量等应符合设

计要求和国家现行有关标准的规定;pipe supports, hangers, anti-shake stent type, material, processing size and quality of welding shall meet the design requirements and the provisions of the existing national standards;

2.7.3管道支架、吊架的安装位置不应妨碍喷头的喷水效果;管道支架、吊架与喷

头之间的距离不宜小于300mm;与末端喷头之间的距离不宜大于750mm;pipe support and hanger installation location should not prevent the nozzle spray effect; distance between pipe supports, hangers and heads of not less than 300 mm; distance between the end of the nozzle should not be greater than 750 mm;

2.7.4配水支管上每一直管段、相邻两喷头之间的管段设置的吊架均不宜少于1

个;当喷头之间的距离小于1.8m时,可隔段设置吊架,但吊架的间距不宜大于

3.6m;with the water manifold on each pipe section has been set hanger adjacent pipe section between the two heads should not be less than 1; when the distance between

the nozzle is less than 1.8m, set every segment hanger, hanger spacing should not be greater than 3.6 m;

2.7.5当管子的公称直径等于或大于50mm时,每段配水干管或配水管设置防晃支

架不应少于1个;当管道改变方向时,应增设防晃支架;When the pipe nominal diameter equal to or greater than 50mm, each water distribution mains or distribution mains set anti-shake bracket should not be less than one; when the pipeline changes direction, the addition of anti-shake bracket;

2.7.6竖直安装的配水干管应在其始端和终端设防晃支架或采用管卡固定,其安

装位置距地面或楼面的距离宜为1.5~1.8m。Vertical installation of water distribution pipe should be fortified at the beginning and the end of Akira stand or fixed pipe card, its installation location away from the ground or floor distance should be 1.5 to 1.8m.

2.8管道穿过建筑物的变形缝时,应采取抗变形措施。穿过墙体或楼板时应加设

套管,套管长度不得小于墙体厚度;穿过楼板的套管其顶部应高出装饰地面20 mm;穿过卫生间或厨房楼板的套管,其顶部应高出装饰地面50 mm,且套管底部应与楼板底面相平。套管与管道的间隙应采用不燃材料填塞密实。Pipe through the building deformation joint resistance to deformation measures should be taken.

Through the wall or floor should be additional casing, the casing shall not be less than the length of the wall thickness; through the floor of the casing should be higher than the top of the decorative ground 20 mm; through the casing of the bathroom or

kitchen floor, the top should be higher the decorative ground 50 mm, and the bottom of the casing should be level with the bottom of the floor face. The clearance of the casing and the pipe should be non-combustible material dense packing.

2.9管道横向安装宜设0.002~0.005的坡度,且应坡向排水管;当局部区域难以利

用排水管将水排净时,应采取相应的排水措施。当喷头数量小于或等于5只时,可在管道低凹处加设堵头;当喷头数量大于5只时,宜装设带阀门的排水管。Horizontal pipe installation should be established slope of 0.002 to 0.005, and the

aspect drains; drainage measures should be taken when the local area is difficult to use the drain to drain water net. When the nozzle number is less than or equal to 5,

additional low recess in the pipe plug; when the nozzle quantities greater than 5, should be fitted with a drain valve.

2.10 配水干管、配水管应做红色或红色环圈标志。Distribution mains, distribution

mains should be done or red ring logo.

2.11管网在安装中间断时,应将管道的敞口封闭。The network installation

intermittent exposure of the pipe should be closed.

3.喷头安装Nozzle installation

3.1 喷头安装应在系统试压、冲冼合格后进行。 3.1 sprinklers should be installed

in the system test pressure wash-qualified.

3.2 喷头安装时,不得对喷头进行拆装、改动、并严禁给喷头附加任何装饰性涂

层。When the nozzle is being installed, no disassembly nozzle, alteration, and any additional decorative coating to the nozzle are strictly prohibited.

3.3喷头安装应使用专用扳手,严禁利用喷头的框架施拧;喷头的框架、溅水盘

产生变形或放原件损伤时,应采用规格、型号相同的喷头更换。Nozzle should be installed using the special wrench, prohibit the use of the framework of the nozzle of tightening; framework of the nozzle, splash plate deformation or put the original injury, should be adopted specifications, replace the nozzle of the same model.

3.4当喷头的公称直径小于10mm时,应在配水干管或配水管上安装过滤器。When

the nozzle nominal diameter less than 10mm, you should install the filter on the

distribution mains or distribution pipes.

3.5安装在易受机械损伤处的喷头,应加设喷头防护罩。Installation vulnerable to

mechanical damage at the nozzle, the nozzle shield should be added.

3.6喷头安装时,溅水盘与吊顶、门、窗、洞口或墙面的距离应符合设计要求。

nozzle splash plate distance from the ceiling, doors, windows, openings or wall

installation, should meet the design requirements.

3.7当梁、通风管道、排管、桥架宽度大于1.2m时,增设的喷头应安装在其腹面

以下部位。When the beams, ventilation ducts, pipes, bridge width is greater than 1.2m the additional sprinklers should be installed in the following parts of the ventral.

3.8当喷头安装在不到顶的隔断附近时,喷头与隔断的水平距离和最小垂直距离

应符合下表规定。When the nozzle installed in less than the top cut off near the nozzle and cut off the horizontal distance and minimum vertical distance should meet the following requirements.

喷头与隔断的水平距离和最小垂直距离(直立与下垂喷头)Nozzle and cut off the

horizontal distance and minimum vertical distance (upright with drooping heads)

3.9当喷头溅水盘高于附近梁底或高于宽度小于1.2m的通风管道腹面时,喷头溅

水盘高于梁底、通风管道腹面的最大垂直距离应符合下表规定。

喷头溅水盘高于梁底、通风管道腹面的最大垂直距离(直立与下垂喷头)

喷头与梁、通风管道的水平距离a(mm) 喷头溅水盘高于梁底、通风管道腹面的最

大垂直距离(mm)When the splash plate nozzle is higher than near the end of beam or higher than the ventral surface of the ventilation ducts of a width of less than 1.2m, the nozzle deflector above the beam at the end of the maximum vertical distance of the ventral surface of the ventilation ducts shall meet the following requirements. Nozzle splash plate is higher than the end of the beam, the maximum vertical distance of the ventral surface of the ventilation ducts (upright and drooping heads)

Nozzle beam, the level of ventilation ducts from a nozzle splash plate (mm) higher than

the end of the beam, the maximum vertical distance of the ventral surface of the ventilation duct (mm)

4.报警阀组安装 alarm valve installation

4.1报警阀组的安装应先安装水源控制阀、报警阀,然后应再进行报警阀辅助管

道的连接。水源控制阀、报警阀与配水干管的连接,应使水流方向一致。报警阀组安装的位置应符合设计要求;当设计无要求时,报警阀组应安装在便于操作的明显位置,距室内地面高度宜为1.2m;两侧与墙的距离不应小于0.5m;正面与墙的距离不应小于1.2m。安装报警阀组的室内地面应有排水设施。Installation of the alarm valve should be installed water control valve, alarm valve should then be further alarm valve auxiliary piping connections. Water control valve, alarm valve and the water

distribution pipe connections should be made consistent with the direction of flow. The alarm valve installation location should meet the design requirements; design No alarm valve should be installed in an obvious location for ease of operation, from the interior floor height appropriate for the 1.2m; both sides of the wall distance of not less than 0.5 m; the distance between the front wall should not be less than 1.2m.

Indoor ground drainage facilities should be installed alarm valve.

4.2 报警阀组附件的安装应符合下列要求:alarm valve accessory installation shall

comply with the following requirements:

4.2.1 压力表应安装在报警阀上便于观测的位置;The pressure gauge should be

installed in the alarm valve to facilitate the location of the observation;

4.2.2 排水管和试验阀应安装在便于操作的位置;Drainage pipe and test valves

should be installed in the position of the ease of operation;

4.2.3 水源控制阀安装应便于操作,且应有明显开闭标志和可靠的锁定设施。

Water control valve installation should be easy to operate, and should be clearly open closed signs and reliable locking facilities.

4.3湿式报警阀组的安装应符合下列要求:Wet alarm valve installation should meet the following requirements

4.3.1应使报警阀前后的管道中能顺利充满水;压力波动时,水力警铃不应发生

误报警。so smoothly filled with water in the pipe before and after the alarm valve; pressure fluctuations, water alarm should not be false alarms.

4.3.2 报警水流通路上的过滤器应安装在延迟器前,而且是便于排渣操作的位置。

Alarm water circulation path of the filter shall be installed before the delay device, but is easy to position slagging operation.

5.其他组件安装Other components installation

5.1水力警铃应安装在公共通道或值班室附近的外墙上,且应安装检修、测试用

的阀门。水力警铃和报警阀的连接应采用镀锌钢管,当镀锌钢管的公称直径为15mm时,其长度不应大于6m;当镀锌钢管的公称直径为20mm时,其长度不宜大于20m;安装后的水力警铃启动压力不应大于0.05Mpa。The water alarm should be installed in the public channel or duty room near the walls of, and installation and maintenance, test valve. Water alarm and alarm valve connection should be made of galvanized steel pipe, galvanized steel pipe nominal diameter of 15mm, the length

should not exceed 6m; galvanized steel pipe nominal diameter of 20mm, the length should not be greater than 20m; installation after starting pressure water alarm should not be greater than 0.05Mpa.

5.2 水流指示器的安装应符合下列要求:Flow indicator shall be installed to meet the following requirements:

5.2.1水流指示器的安装应在管道试压和冲冼合格后进行,水流指示器的规格、型

号应符合设计要求;The flow indicator shall be installed in the pipeline pressure test and wash-qualified, flow indicator, specifications, models should meet the design

requirements;

5.2.2水流指示器应竖直安装在水平管道上侧,其动作方向应和水流方向一致;安

装后的水流指示器浆片、膜片应动作灵活,不应与管壁发生碰擦。The flow indicator shall be mounted vertically on the side of the horizontal pipe, its direction of motion and the direction of flow; the flow indicator lodicule after installation, flexible

diaphragm action should be, and should not be confused with the wall grazing.

5.3信号阀应安装在水流指示器前的管道上,与水流指示器之间的距离不宜小于

300mm。Signal valve should be installed in the pipe before the flow indicator, the distance between the flow indicator should not be less than 300mm.

5.4排气阀的安装应在系统管网试压和冲冼合格后进行;排气阀应安装在配水干管顶

部、配水管的末端,且应确保无渗漏。exhaust valve should be installed in the system pipe network pressure test and wash qualified; exhaust valve should be installed at the end of the top of distribution mains, distribution mains, and shall ensure that no

leakage.

5.5控制阀的规格、型号和安装位置均应符合设计要求;安装方向应正确,控制阀

内应清洁、无堵塞、无渗漏;主要控制阀应加设启闭标志;隐蔽处的控制阀应在明显处设有指示其位置的标志。specification, model and installation location of the control valve should be in accordance with the design requirements; install the correct direction, the control valve should be clean, no plug, no leakage; the main control valve opening and closing flag should be added; shelter control valve should be prominent place has to indicate the location of the flag.

5.6节流装置应安装在公称直径不小于50mm的水平管段上;减压孔板应安装在管

道内水流转弯处下游一侧的直管上,且与转弯处的距离不应小于管子公称直径的2倍。Throttling device should be installed in the horizontal pipe nominal diameter of not less than 50mm; decompression orifice should be installed on the downstream side of the water pipe bend on the straight pipe, tube and turn at a distance of not less than nominal diameter 2 times.

5.7压力开关应竖直安装在通往水力警铃的管道上,且不应在安装中拆装改动。The

pressure switch should be mounted vertically on the pipe leading to the water alarm, and should not be used in the installation disassembly changes.

5.8末端试水装置宜安装在系统管网末端或分区管网末端。End water device should

be installed at the end of the pipe network or partition the end of the pipe network.

6.系统试压和冲冼System pressure test and wash

1)一般规定General provisions

( 1).管网安装完毕后,应对其进行强度试验、严密性试验和冲冼。After installation of the pipe network, should the strength test, tightness test and wash.

(2).强度试验和严密性试验宜用水进行。干式喷水灭火系统、预作用喷水灭火

系统应做水压试验和气压试验。 Strength test and tightness test should be

performed with water. Dry sprinkler systems, pre-action sprinkler system hydraulic test and pressure test should be done.

3.系统试压前应具备下列条件: System pressure test shall meet the following

conditions:

(1)埋地管道的位置及管道基础、支墩等经复查符合设计要求; Location of buried

pipelines and pipeline infrastructure and buttress have been inspected and meet the design requirements;

(2)试压用的压力表不少于2只;精度不应低于1.5级,量程应为试验压力值的

1.5~ 2倍; The gauge pressure test of not less than 2; accuracy should not be less than 1.5, the range should be 1.5 to 2 times the test pressure value; System pressure test shall meet the following conditions: